-

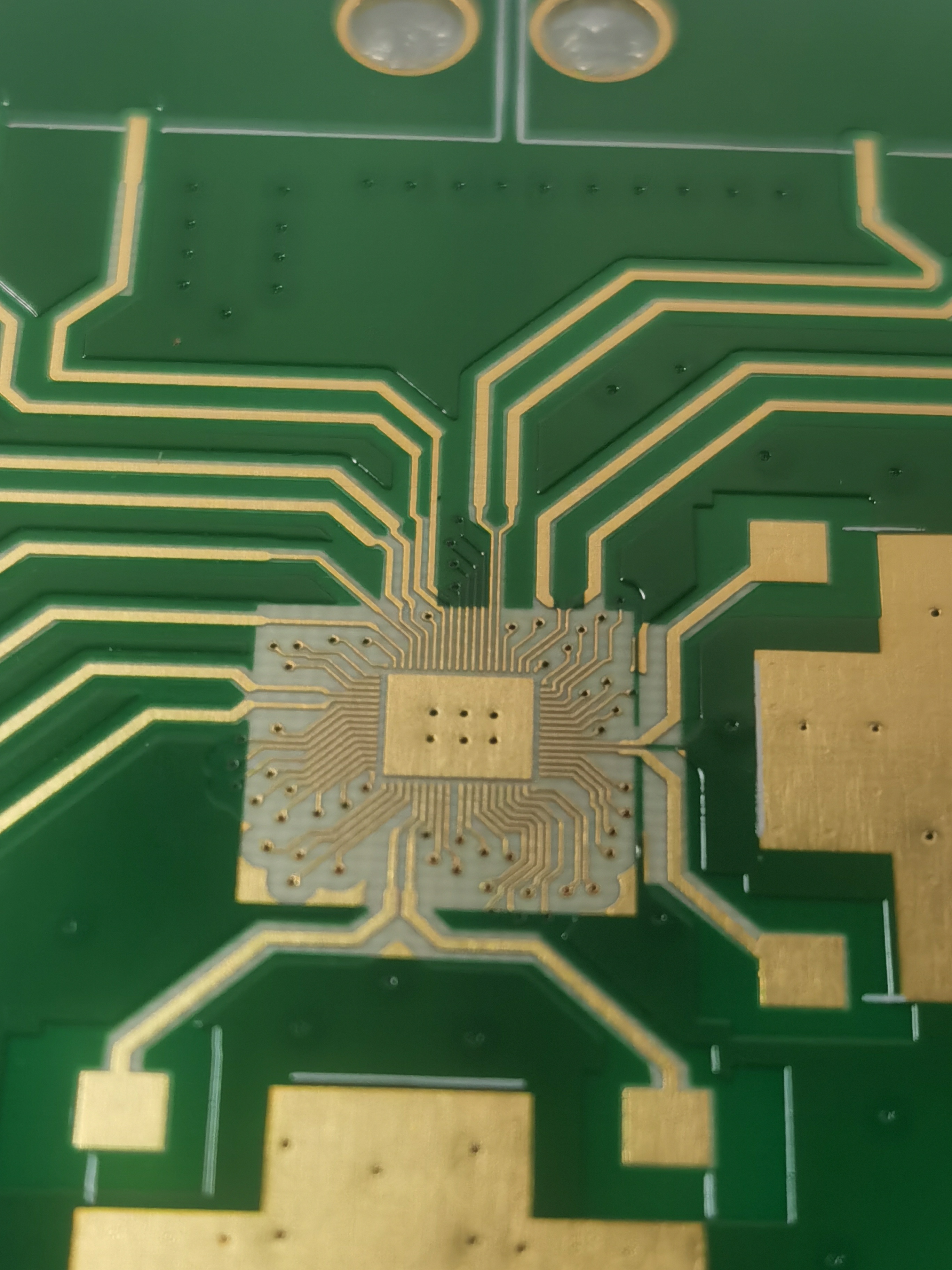

ENEPIG for RO4350B with blind vias from L1-L2,L3-L4

ENEPIG for RO4350B with blind vias from L1-L2,L3-L4¥ 0.00Buy now

-

4 layer RO4350B PCB with blind and ENEPIG

4 layer PCB

Material:All is RO4350B,6.6mil

Thickness:0.7mm

Surface: ENEPIG

Blind vias L1-L2,L3-L4

Min trace/space:4/4mil¥ 0.00Buy now

-

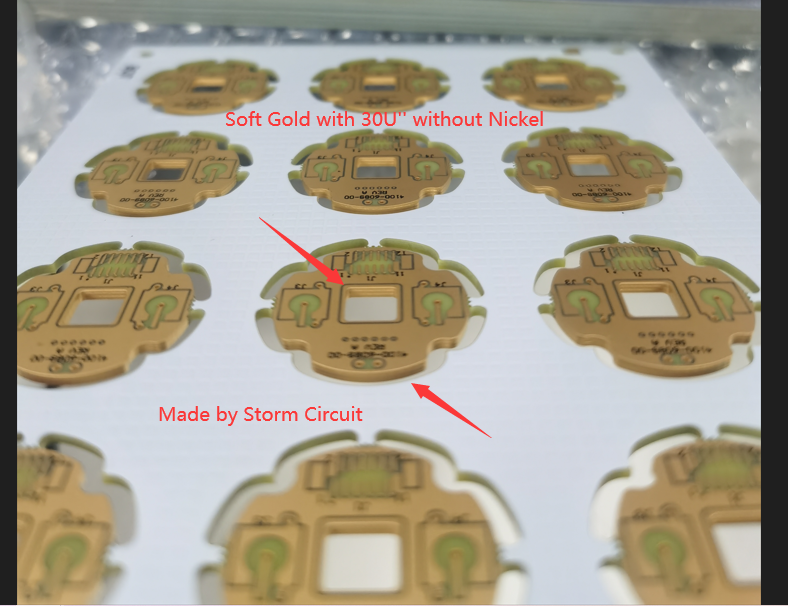

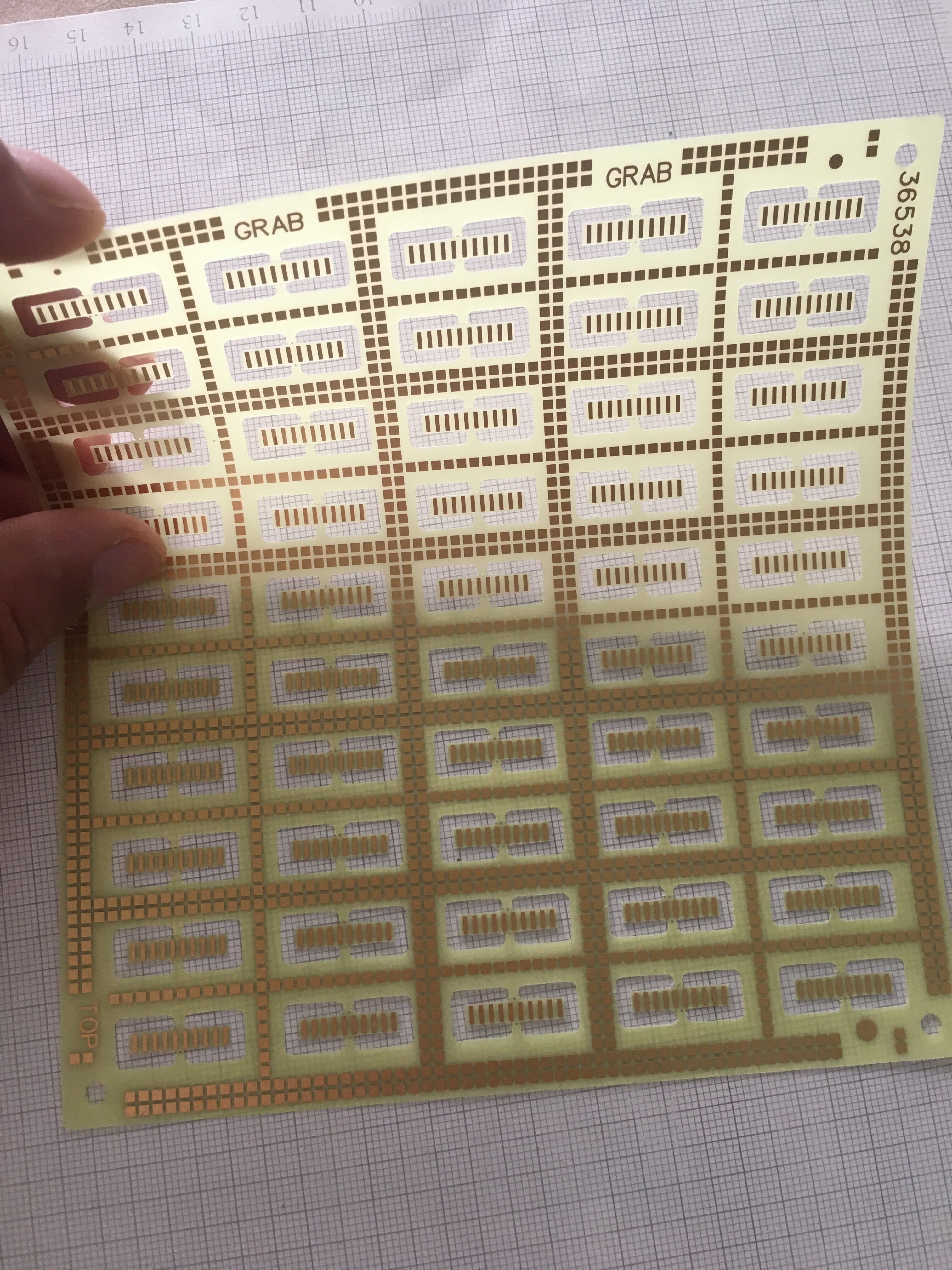

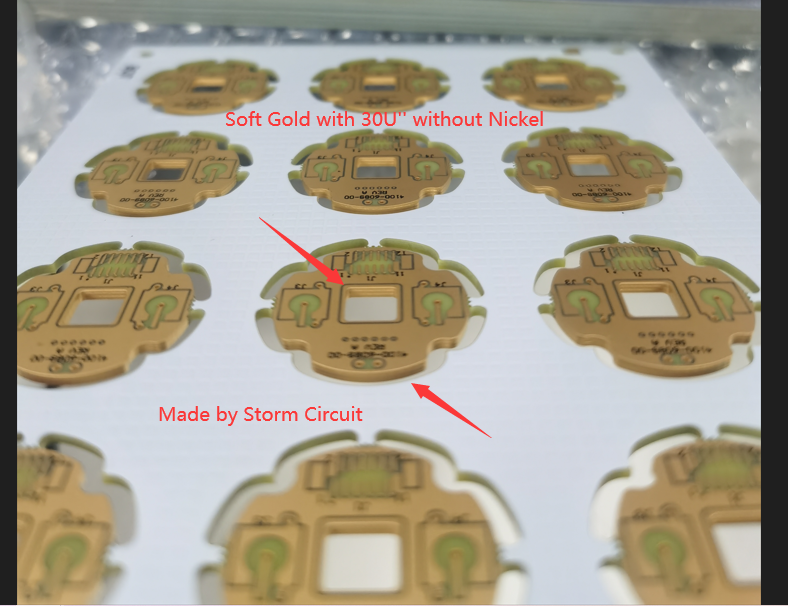

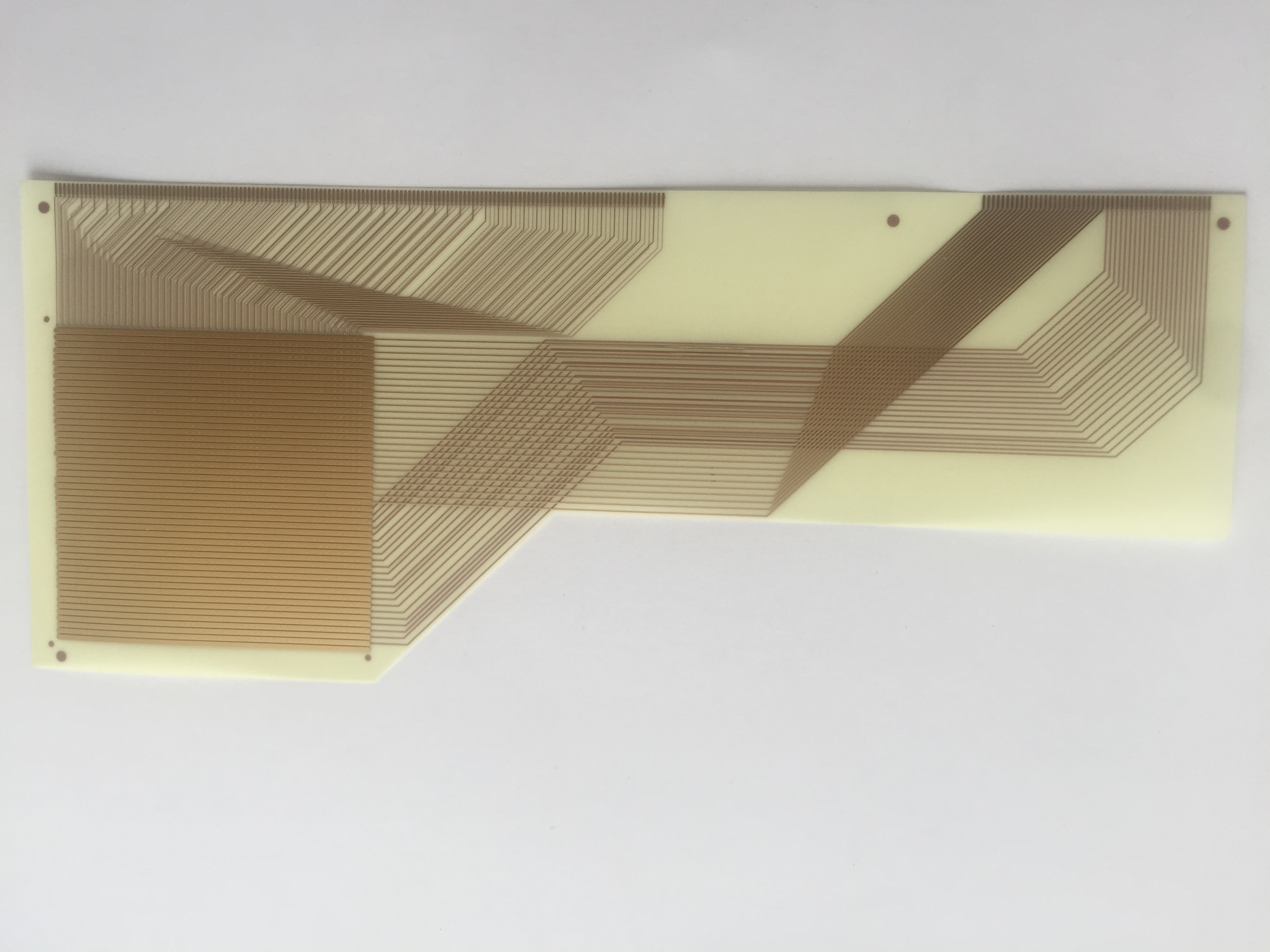

Soft Gold plating with 30 Micro inch PCB

FR4 :4 layer 1.6mm 1oz

Full gold at top and bottom side in units

Soft Gold with 30 micro inch

Edge plating

Black solder mask,white silkscreen¥ 0.00Buy now

-

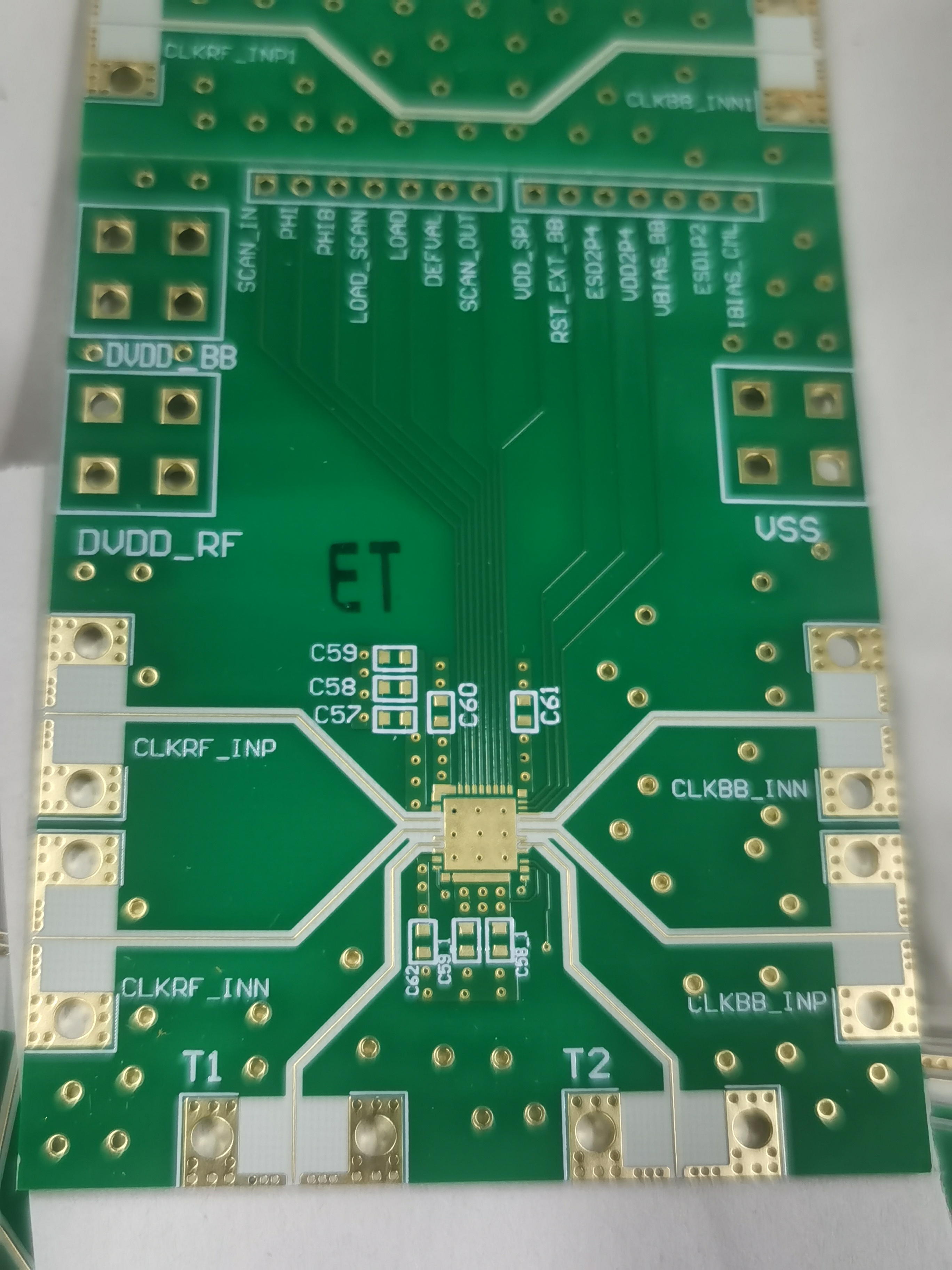

8 Layer PCB with ENEPIG

8 Layer PCB

ENEPIG

1.6mm TG170

trace/space 0.1/0.1mm

min hole 0.15mm¥ 0.00Buy now

-

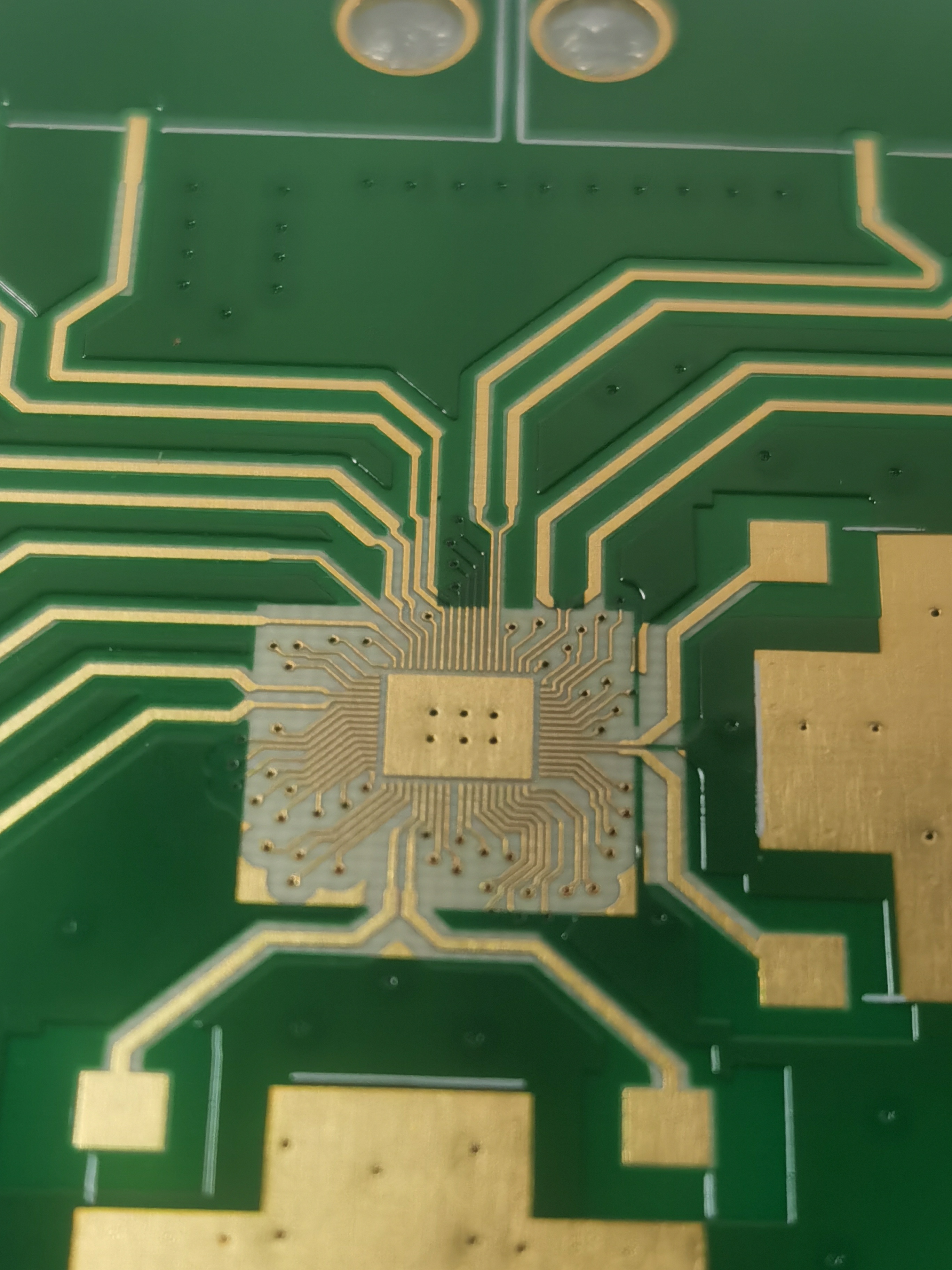

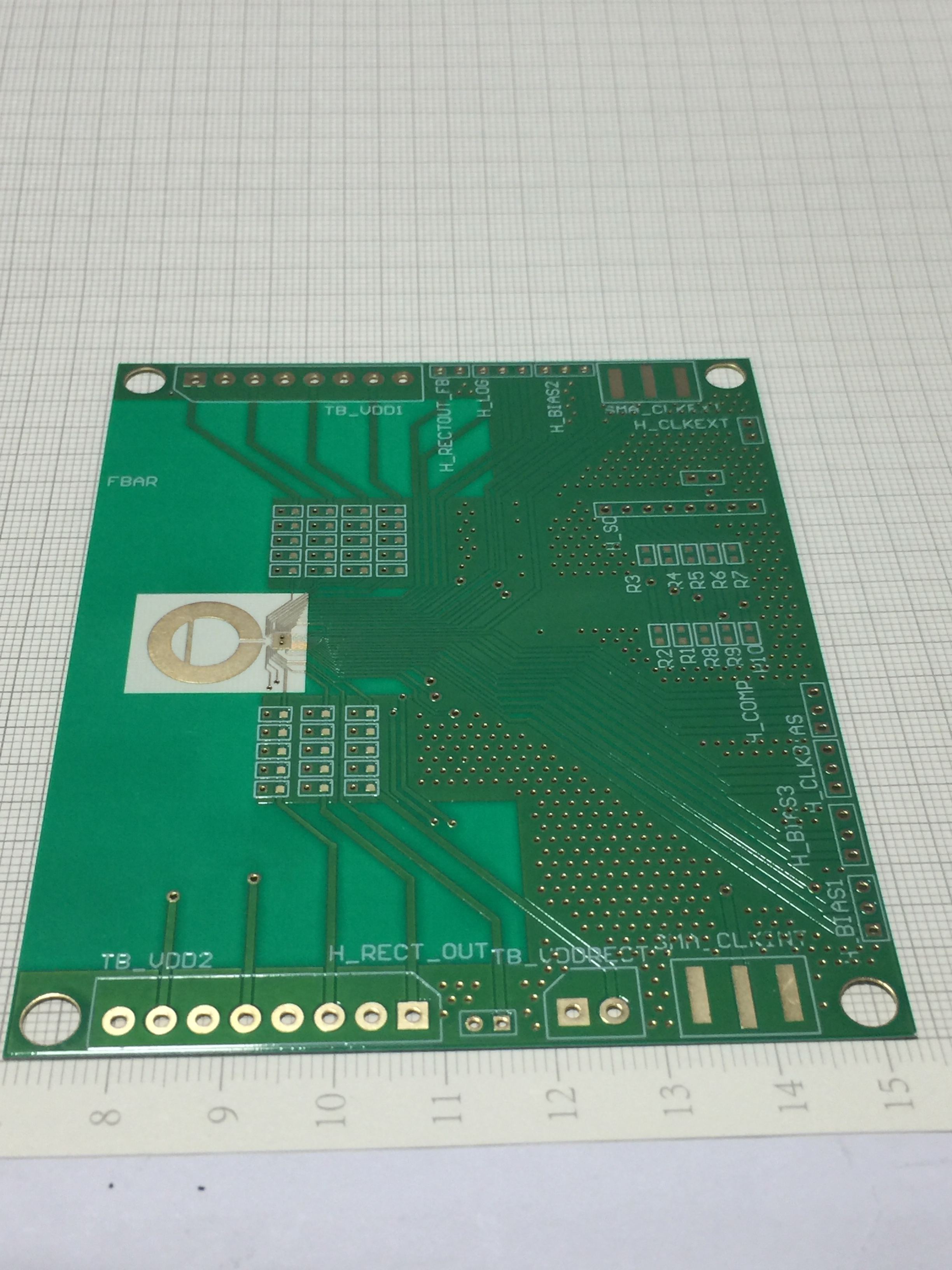

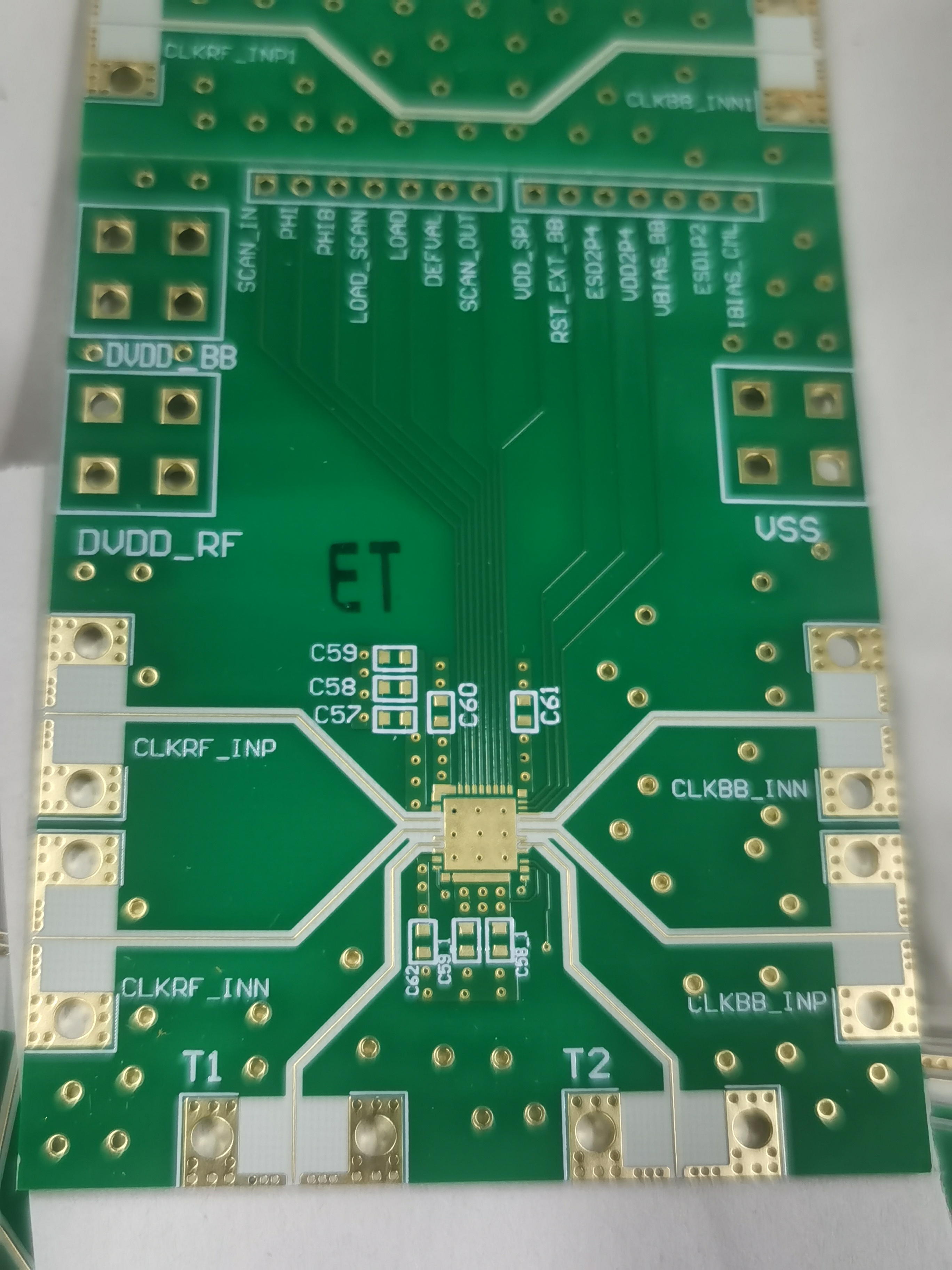

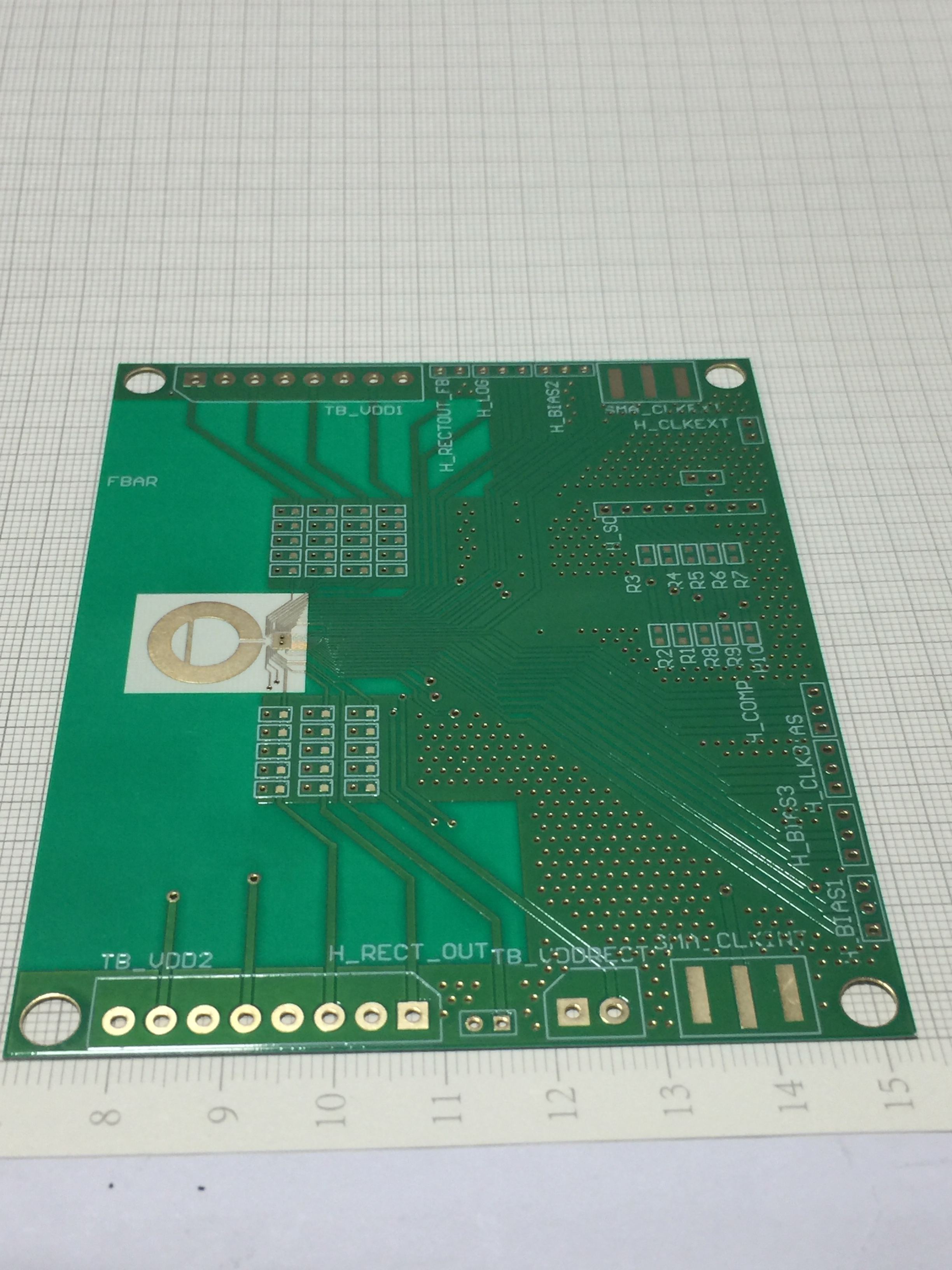

High frequency PCB with ENEPIG designed by Oregon State University

High frequency PCB with ENEPIG designed by Oregon State University

Material:RO4350B

4 Layer 1.0mm

Surface finish:ENEPIG (ENEPIG-Electroless Nickel Electroless Palladium Immersion Gold)

Min trace/space 3/3mil¥ 0.00Buy now

-

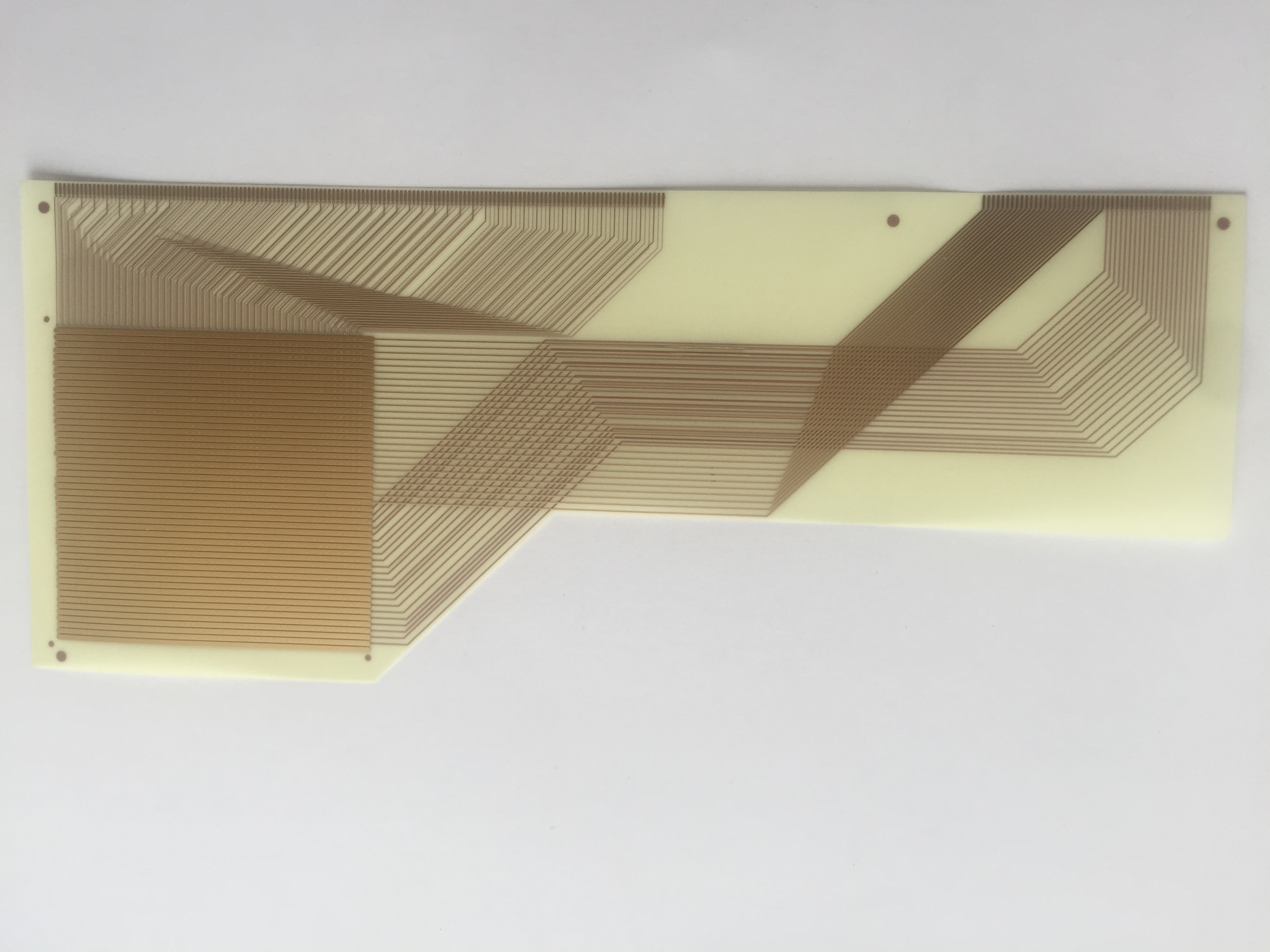

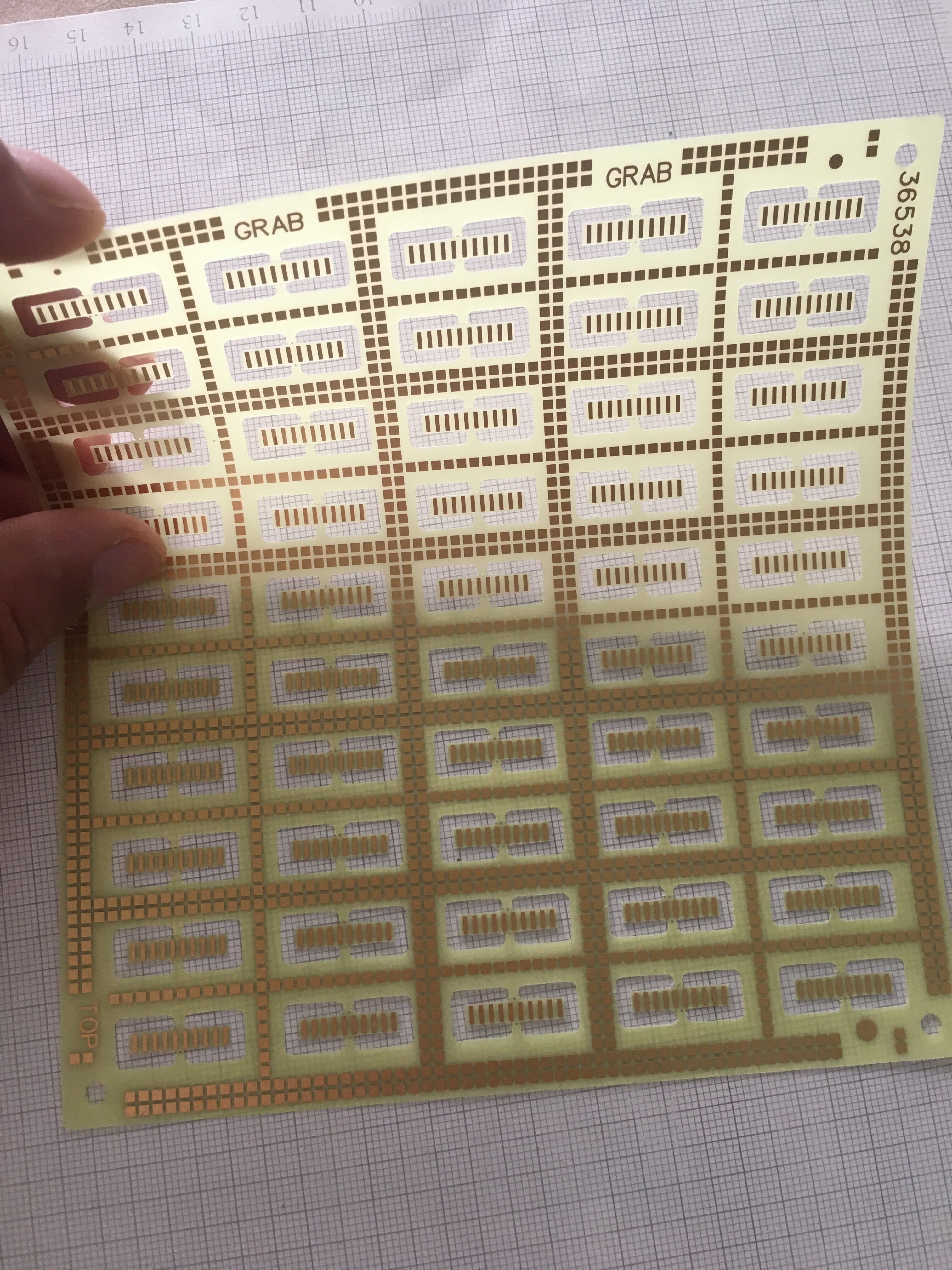

ENEPIG PCB with 0.2mm

0.2mm ENEPIG PCB

FR4 material but 0.2mm only

Very thin

Full Gold

No solder mask¥ 0.00Buy now

-

0.2mm ENEPIG PCB

0.2mm ENEPIG PCB

min trace/space 3/3mil

Rigid PCB with 0.2mm

Nano applications¥ 0.00Buy now

-

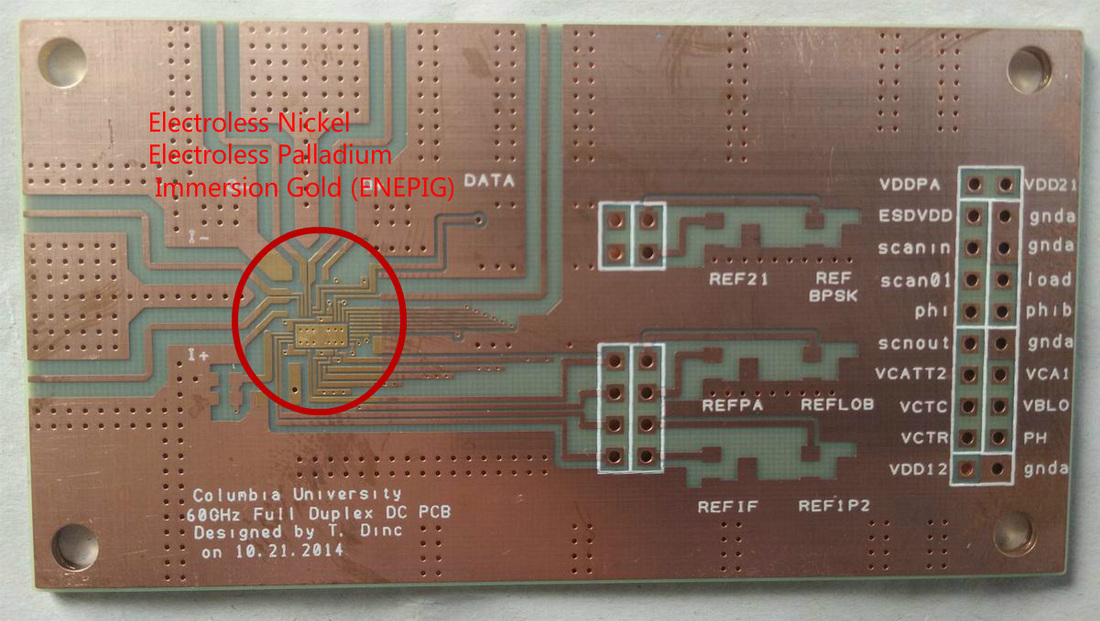

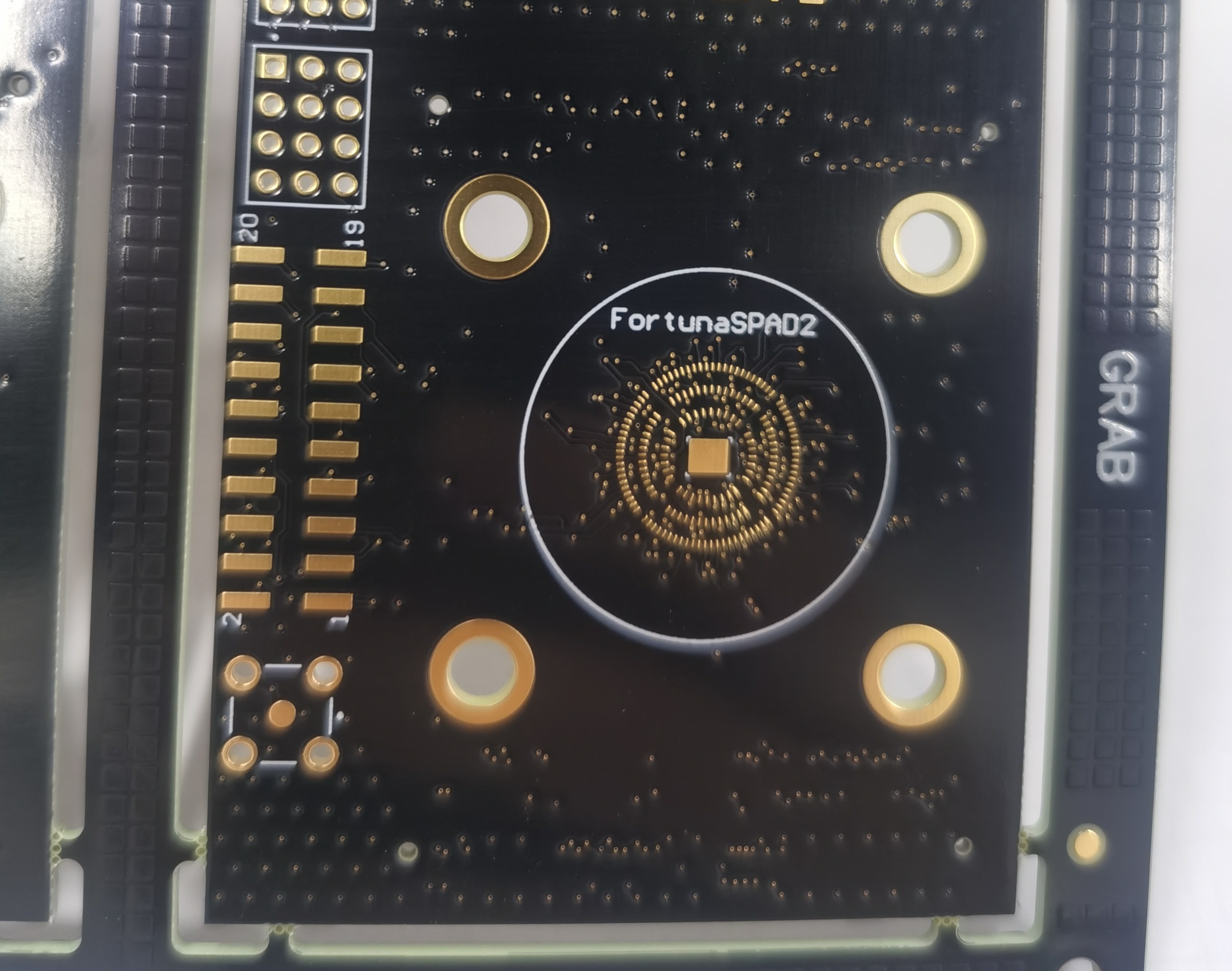

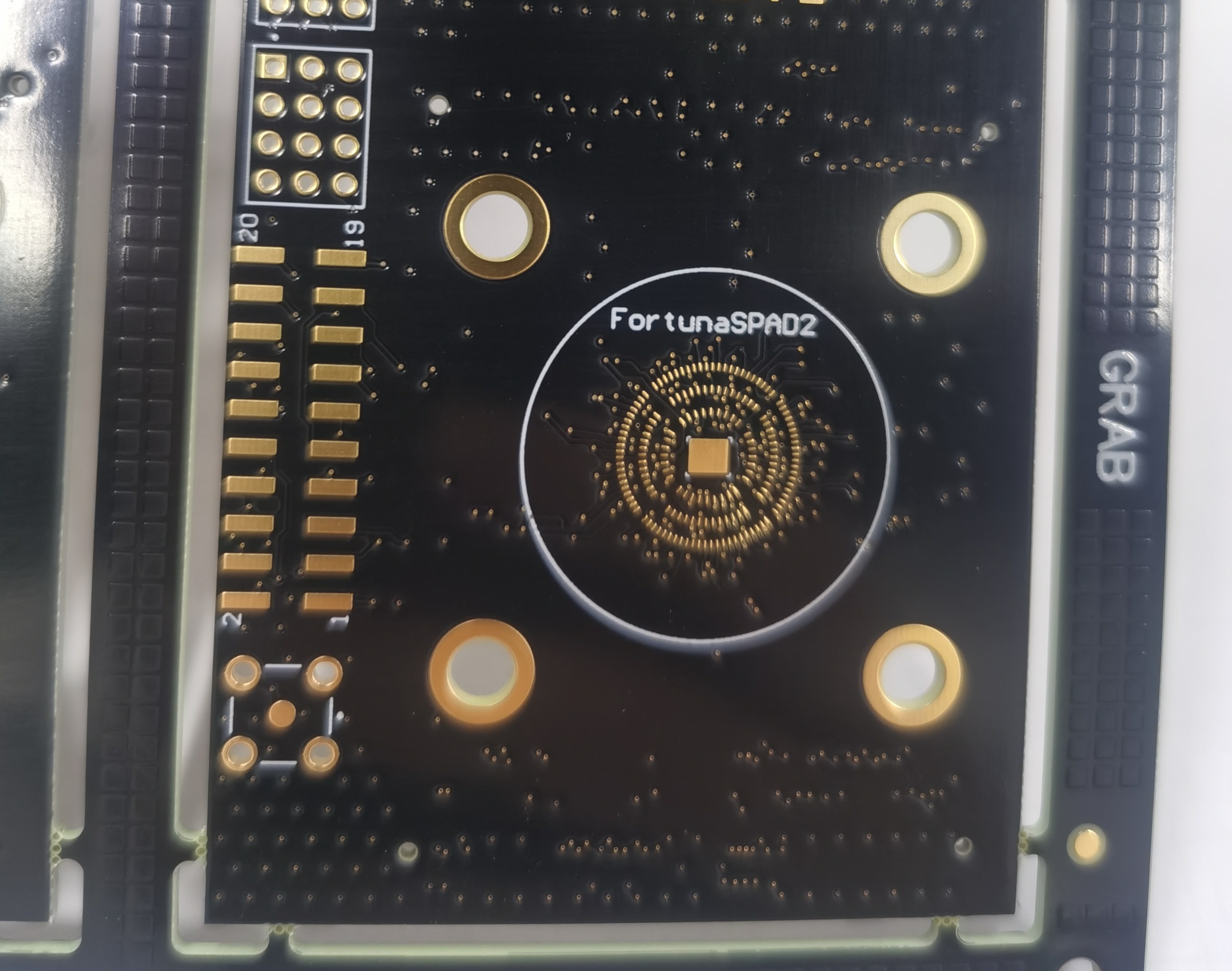

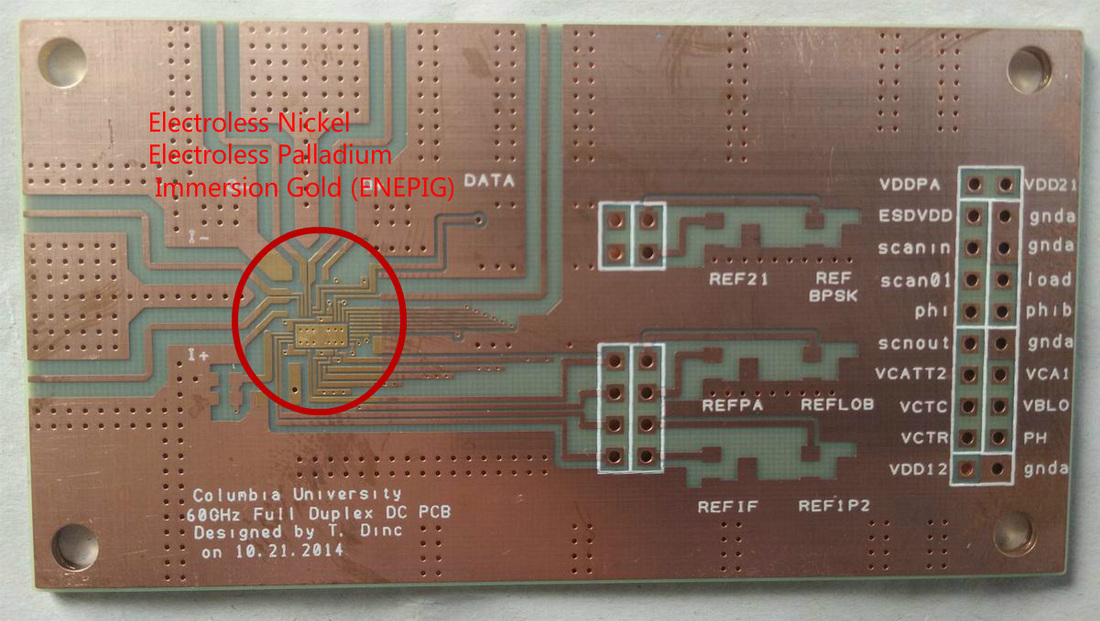

ENEPIG PCB designed by Columbia University

ENEPIG PCB designed by Columbia University

ENEPIG PCB made by Storm Circuit¥ 0.00Buy now