-

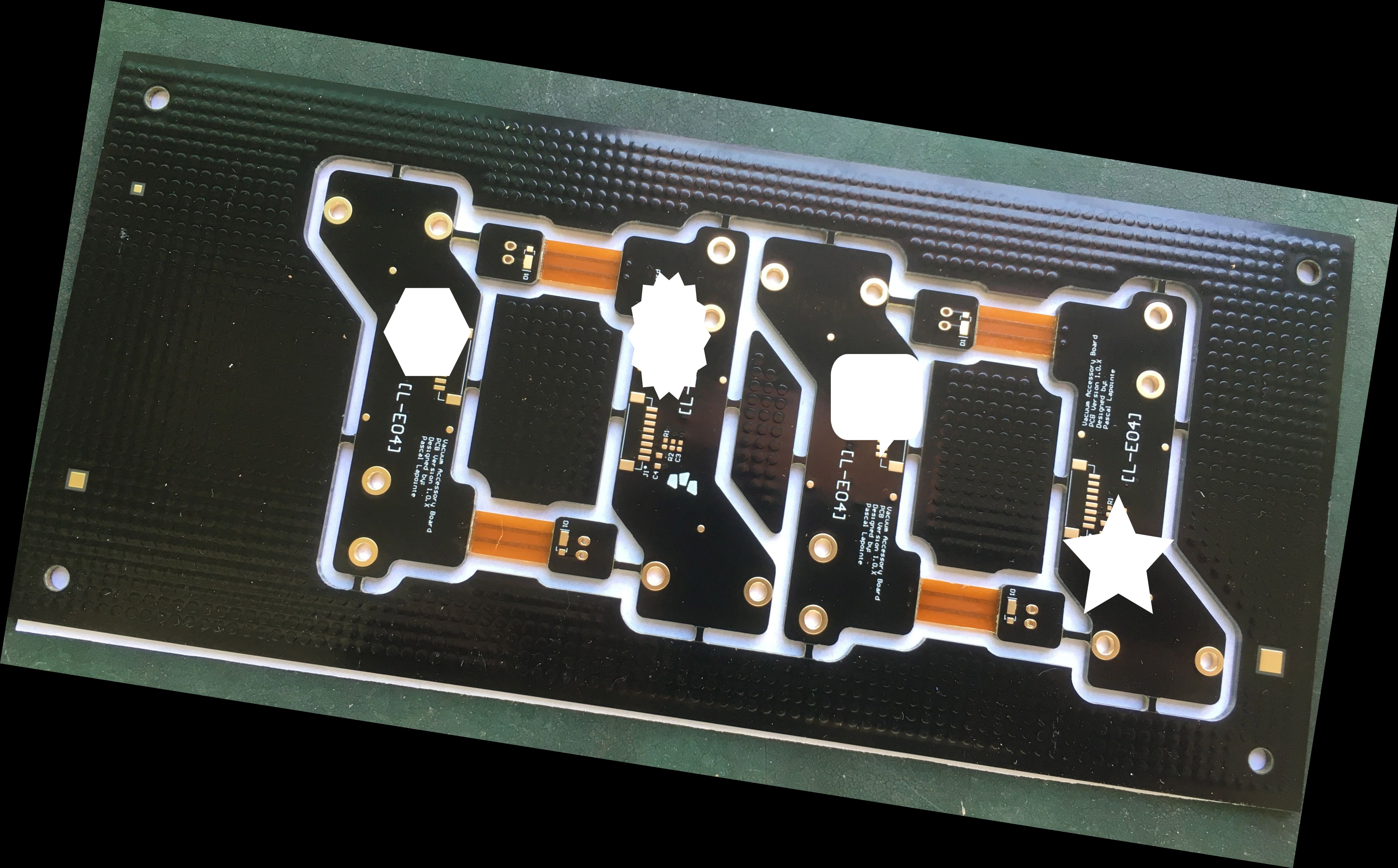

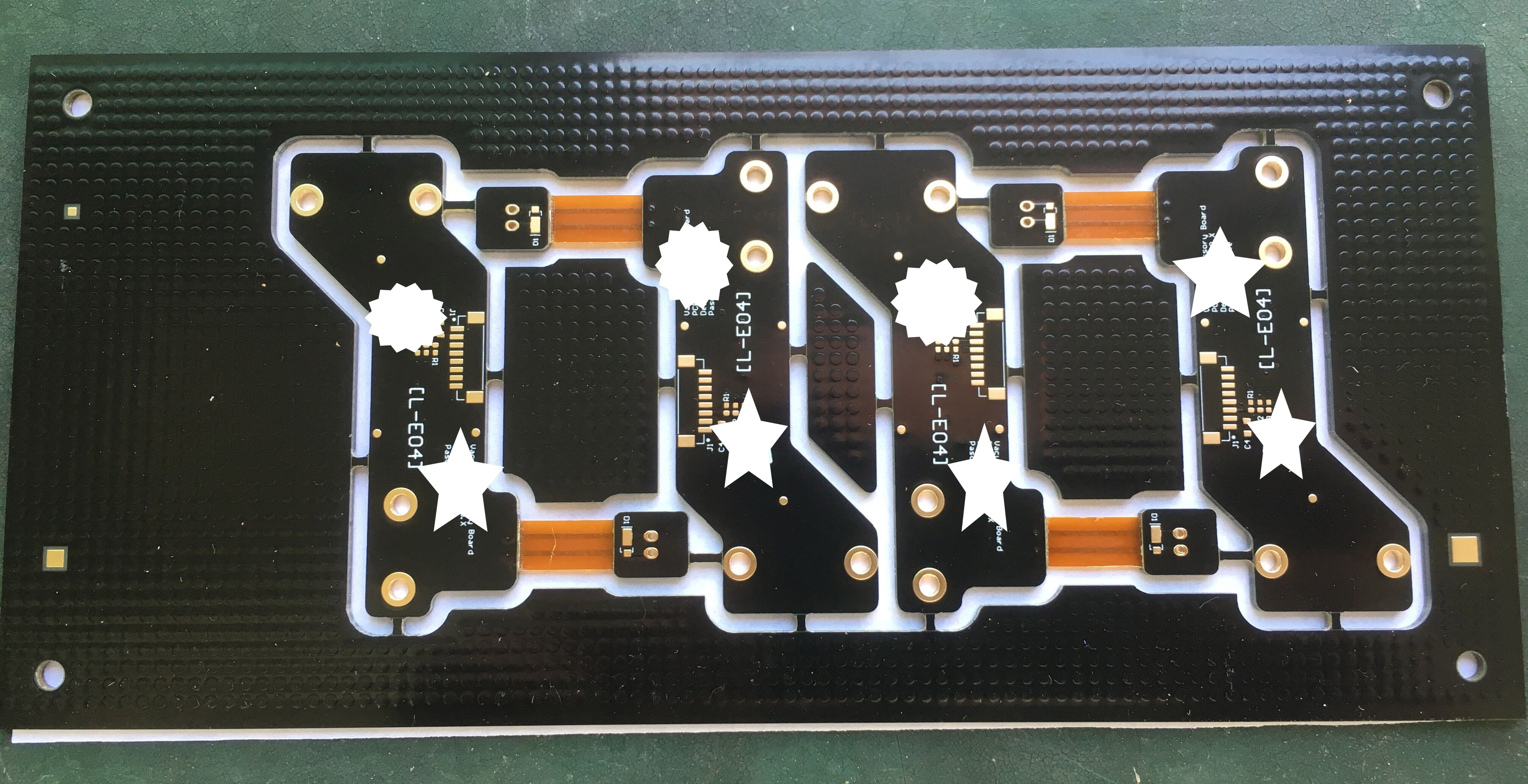

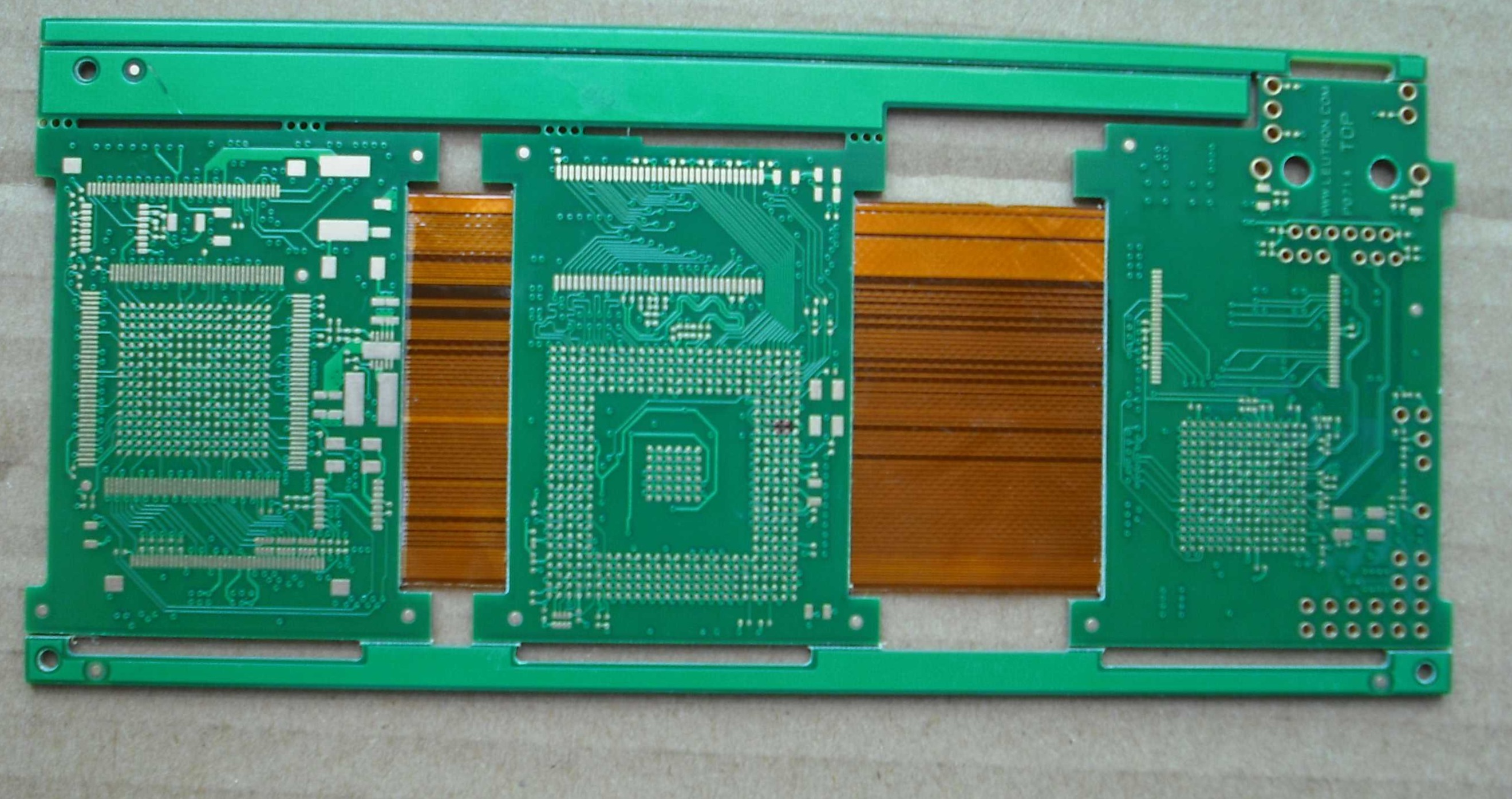

4 layer rigid-flex PCB with HDI design

¥ 0.00Buy now

-

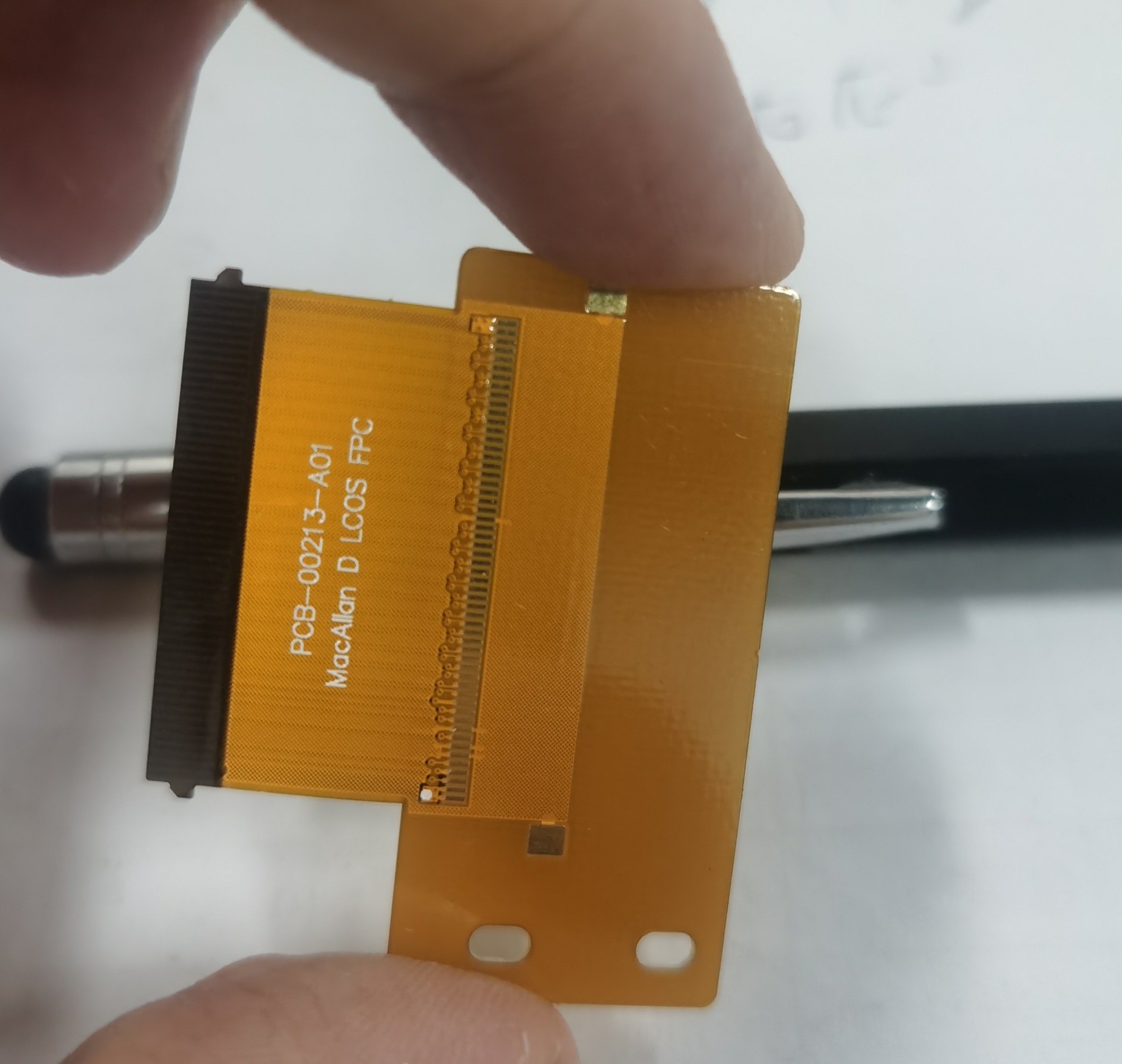

2 Layer FPC with hard gold plating 30U''

2 Layer FPC with hard gold plating 30U''¥ 0.00Buy now

-

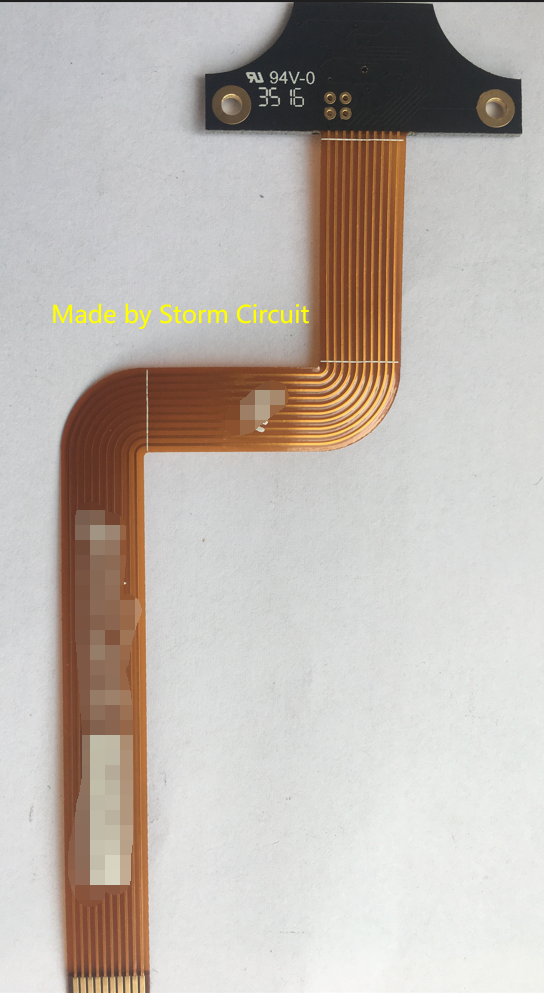

2 layer FPC with quick turn in 3 days

0.2mm

Flex PCB

Stiffener with 0.3mm thickness¥ 0.00Buy now

-

4 layer Flex PCB with 0.25mm thickness

4 layer

Flexible PCB

0.25mm

Stiffener¥ 0.00Buy now

-

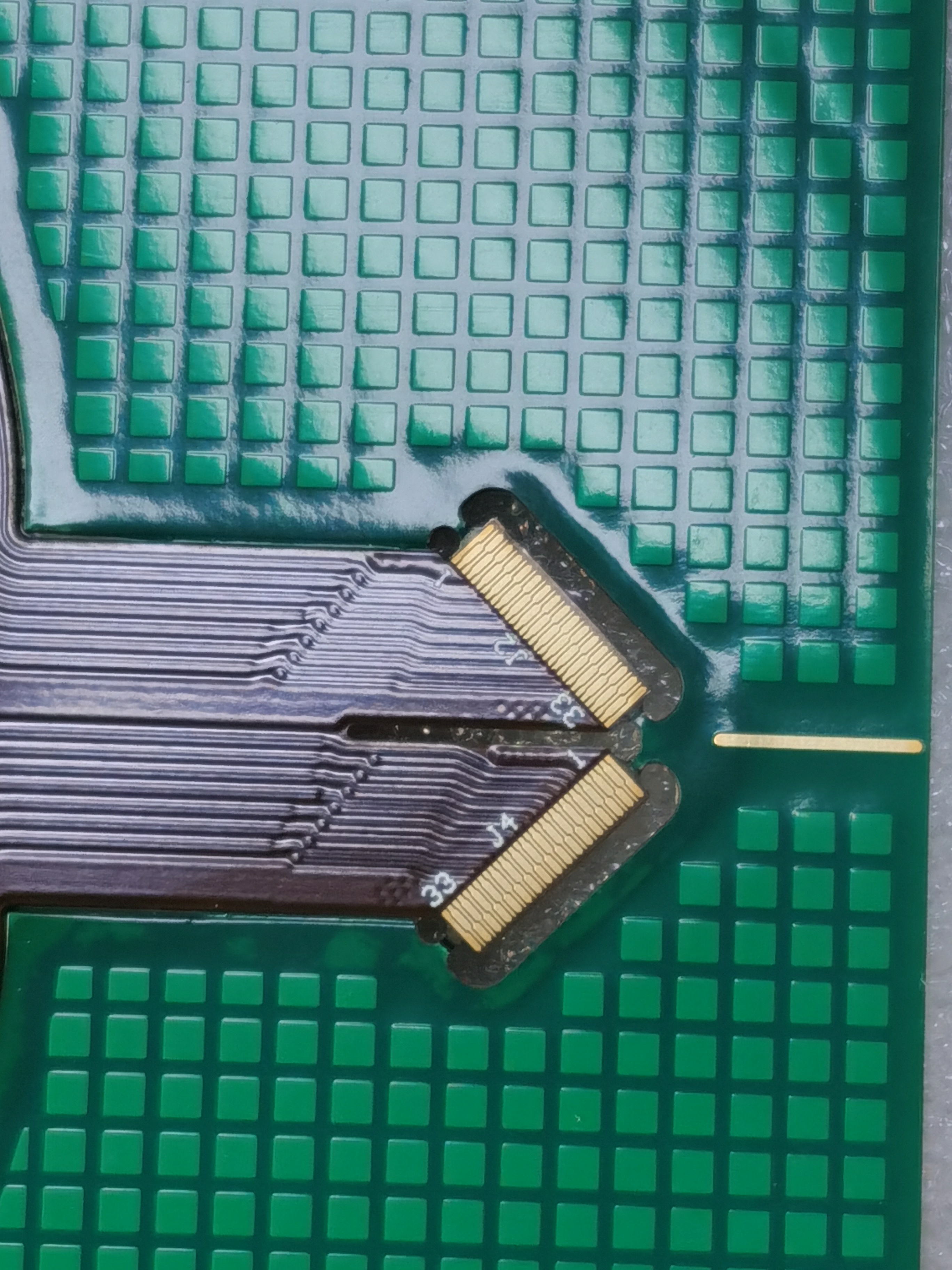

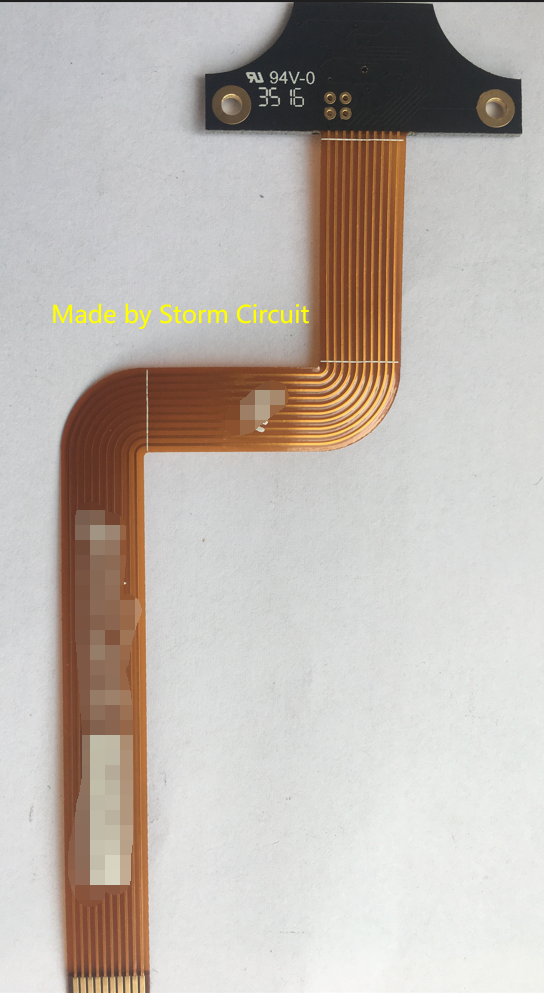

2 Layer FPC with 0.1/0.1mm gold fingers

2 Layer FPC

Thickness 0.2mm

min trace/space 0.1/0.1mm

FR4 stiffener total thickness 0.8mm

Storm Circuit loaded components too¥ 0.00Buy now

-

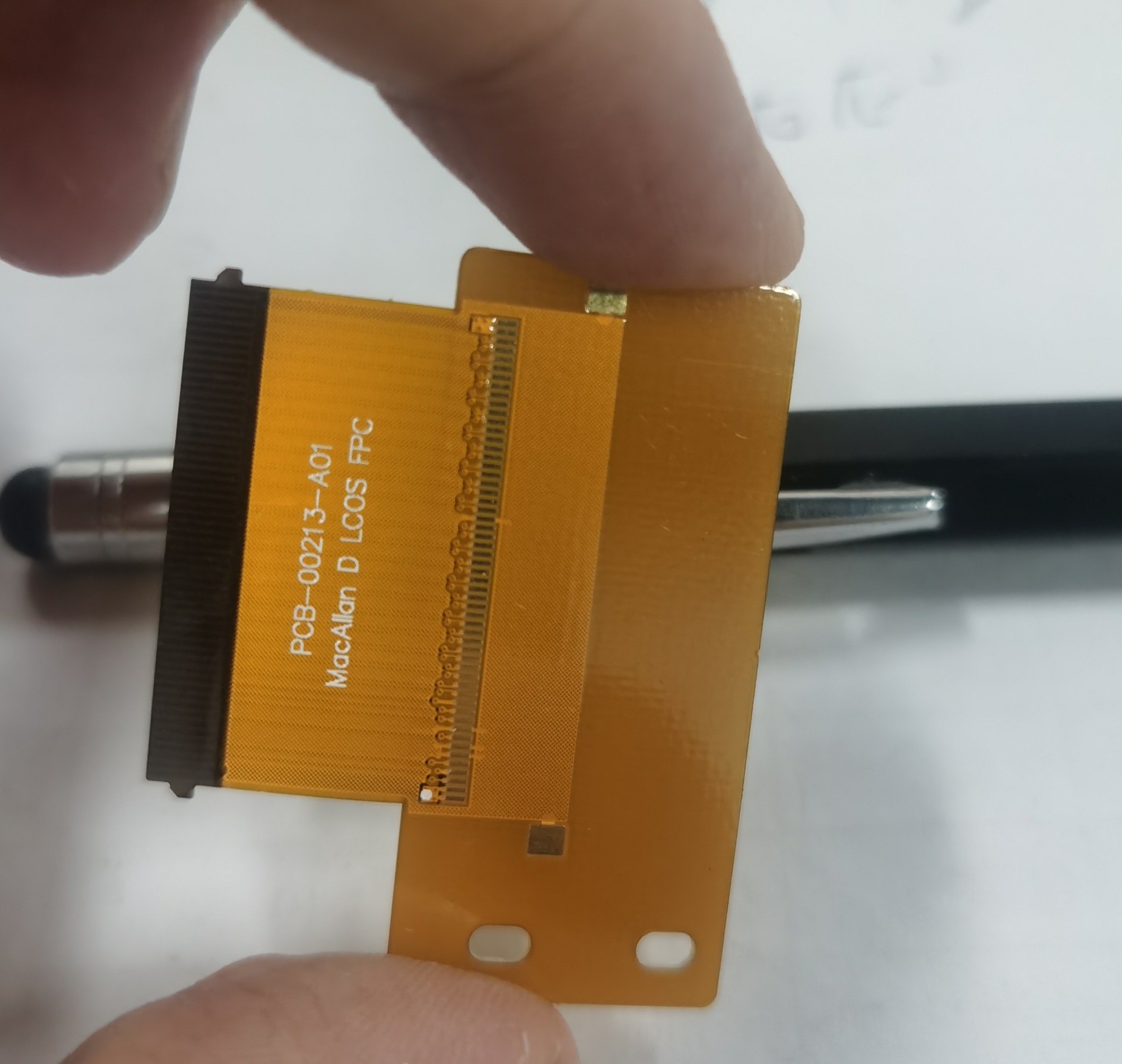

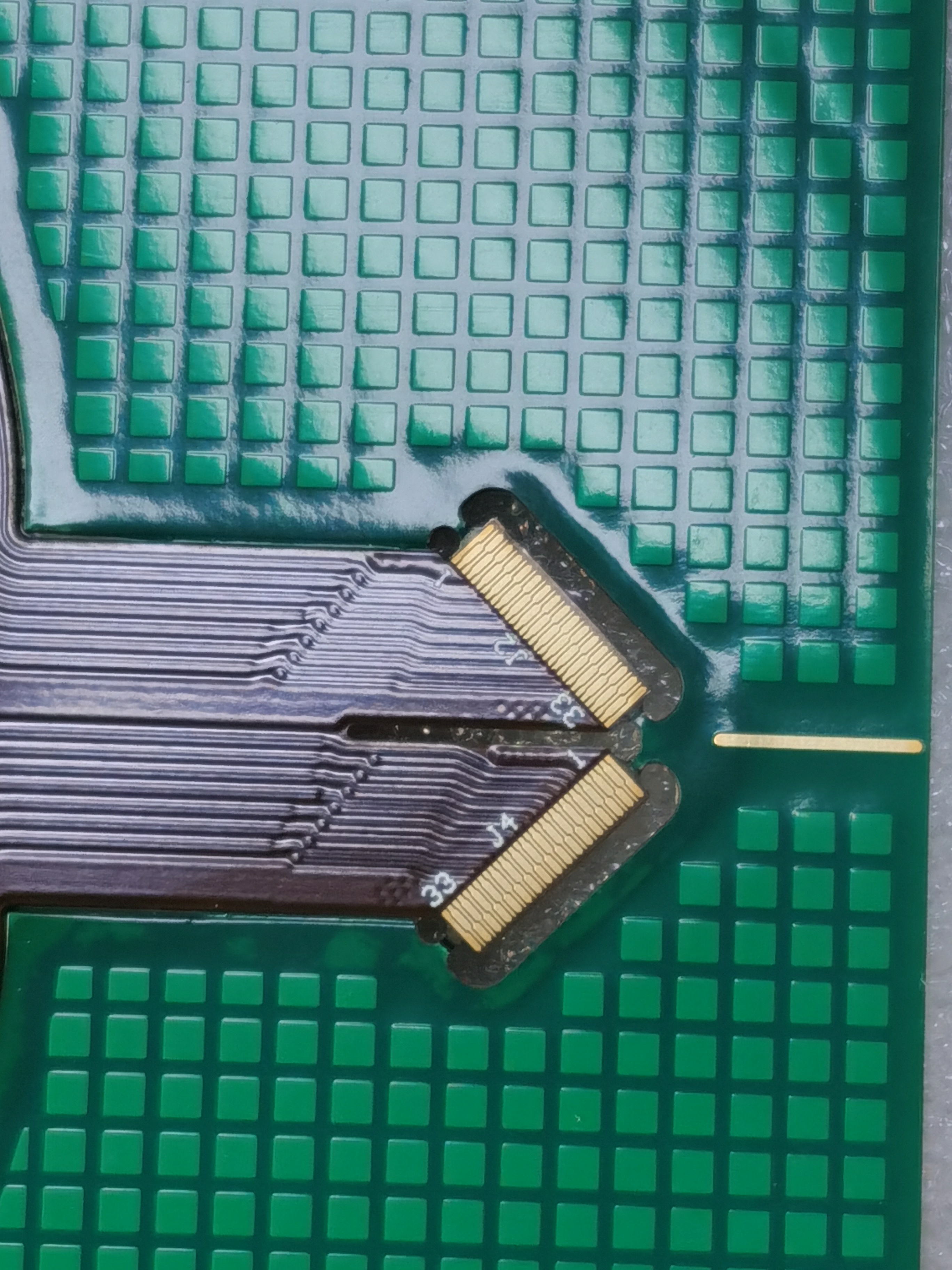

2 layer Flexible PCB with 1.0mm stiffener

2 layer Flexible PCB

Quick turn in 3 days

FR4 1.0mm +PI stiffener

Gold fingers

Impedance

trace/space 0.1/0.1mm¥ 0.00Buy now

-

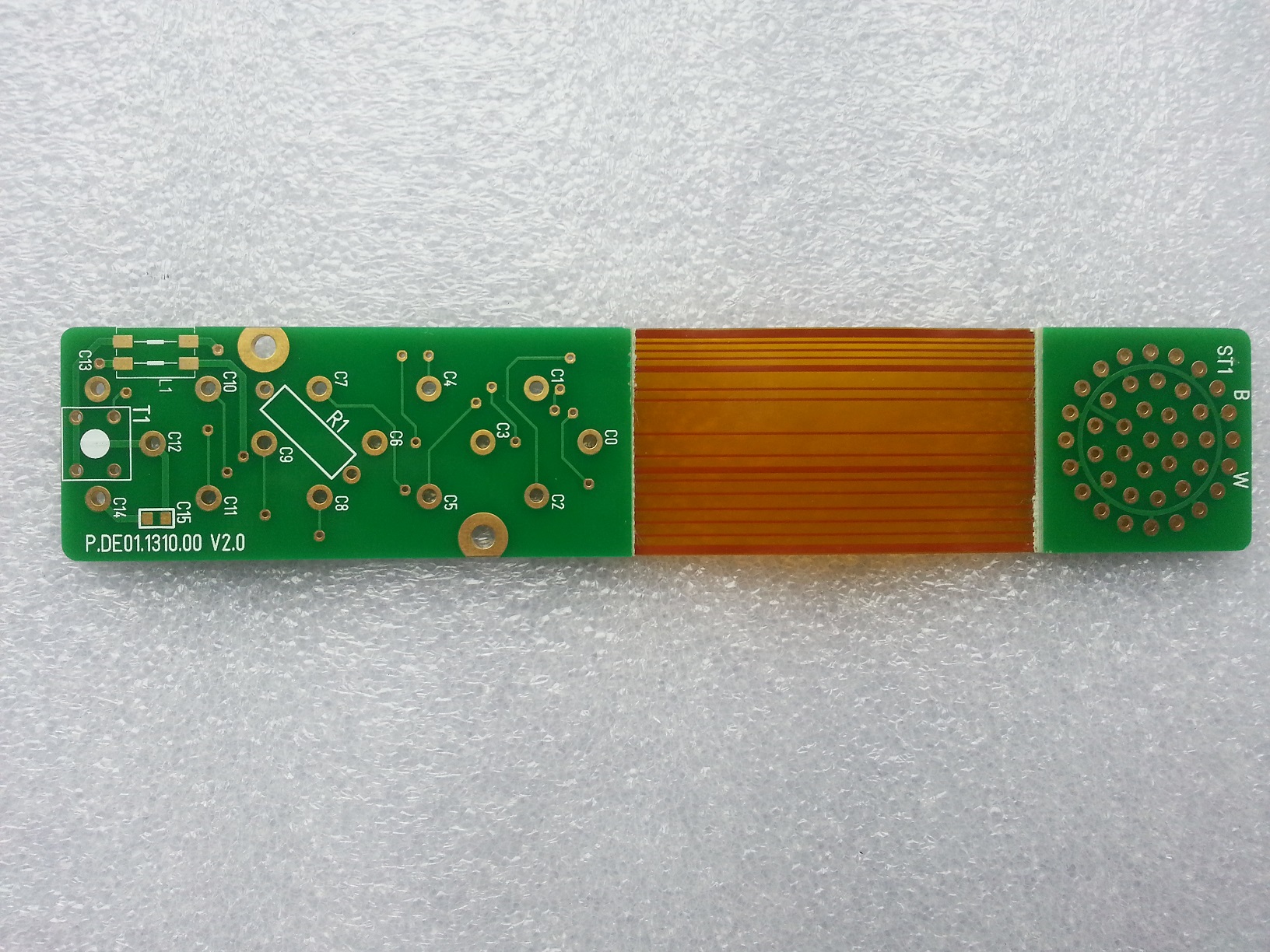

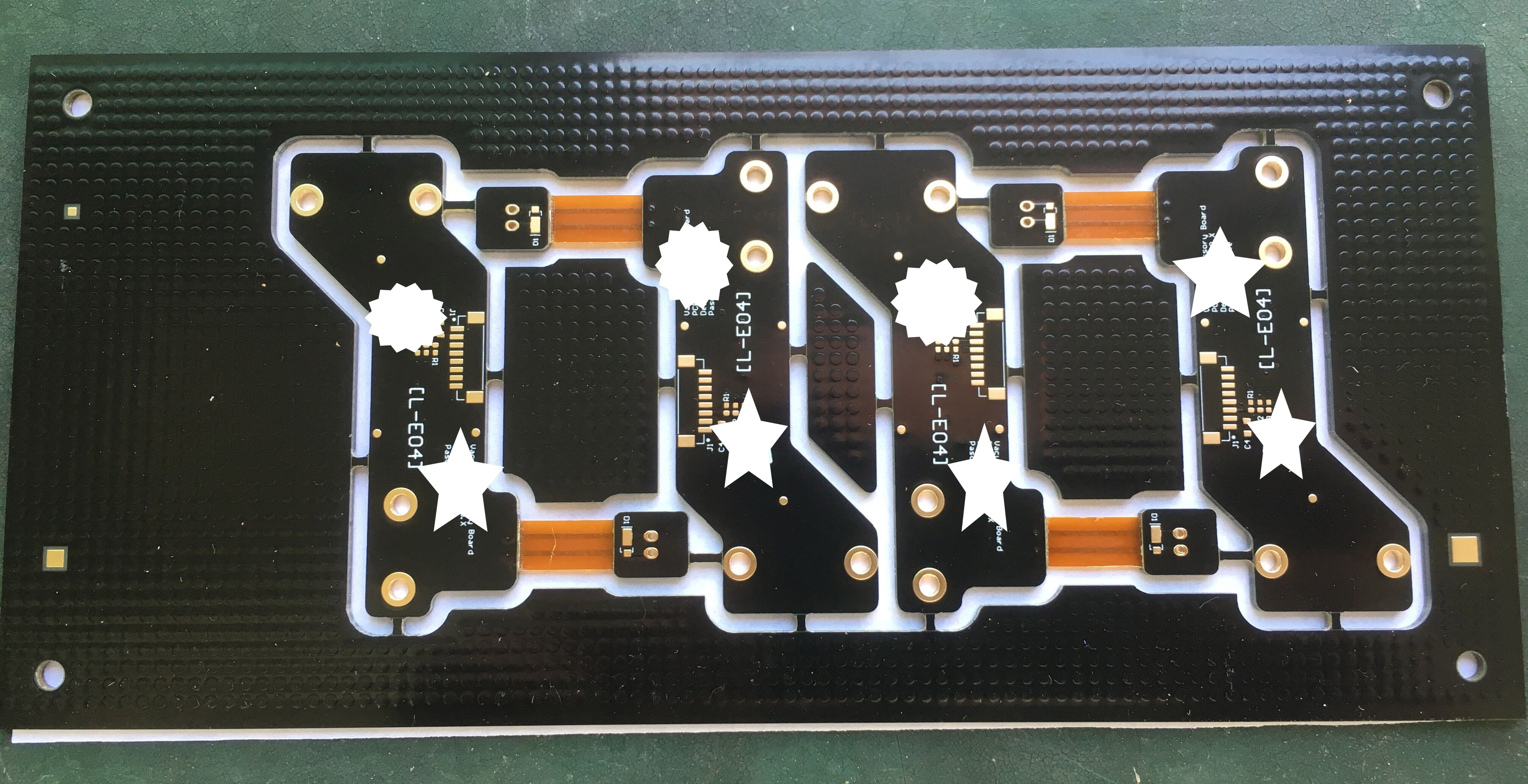

4 layer rigid-flex PCB

4 layer rigid-flex PCB

FR4+PI

1.6mm+0.2mm¥ 0.00Buy now

-

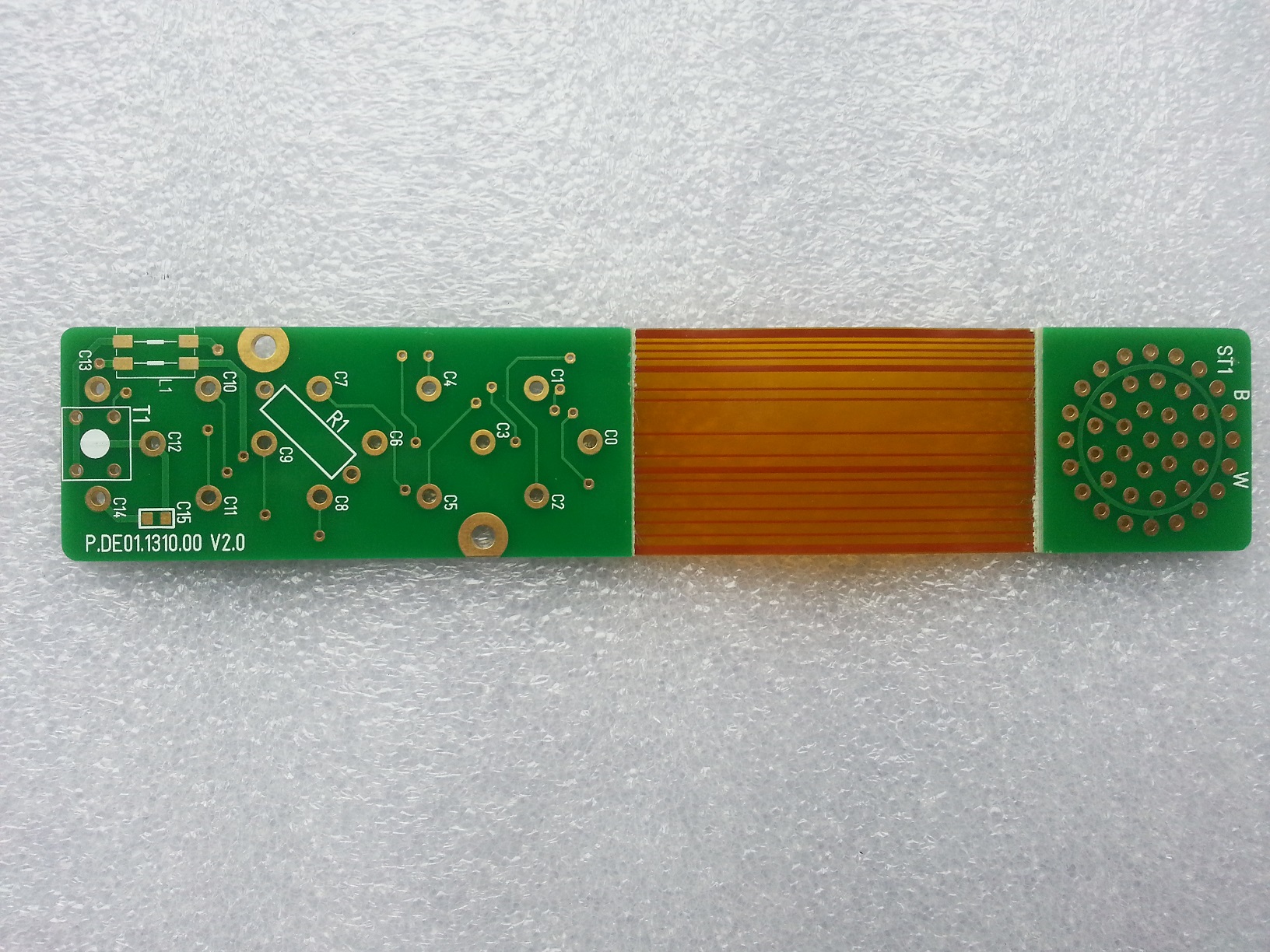

2 layer rigid-flex PCB

2 layer rigid-flex PCB

1.6mm+0.1mm¥ 0.00Buy now

-

2 layer rigid-flex PCB with 1.2mm

2 layer rigid-flex PCB with 1.2mm

FR4+PI

1.2mm+0.1mm

Stiffener¥ 0.00Buy now

-

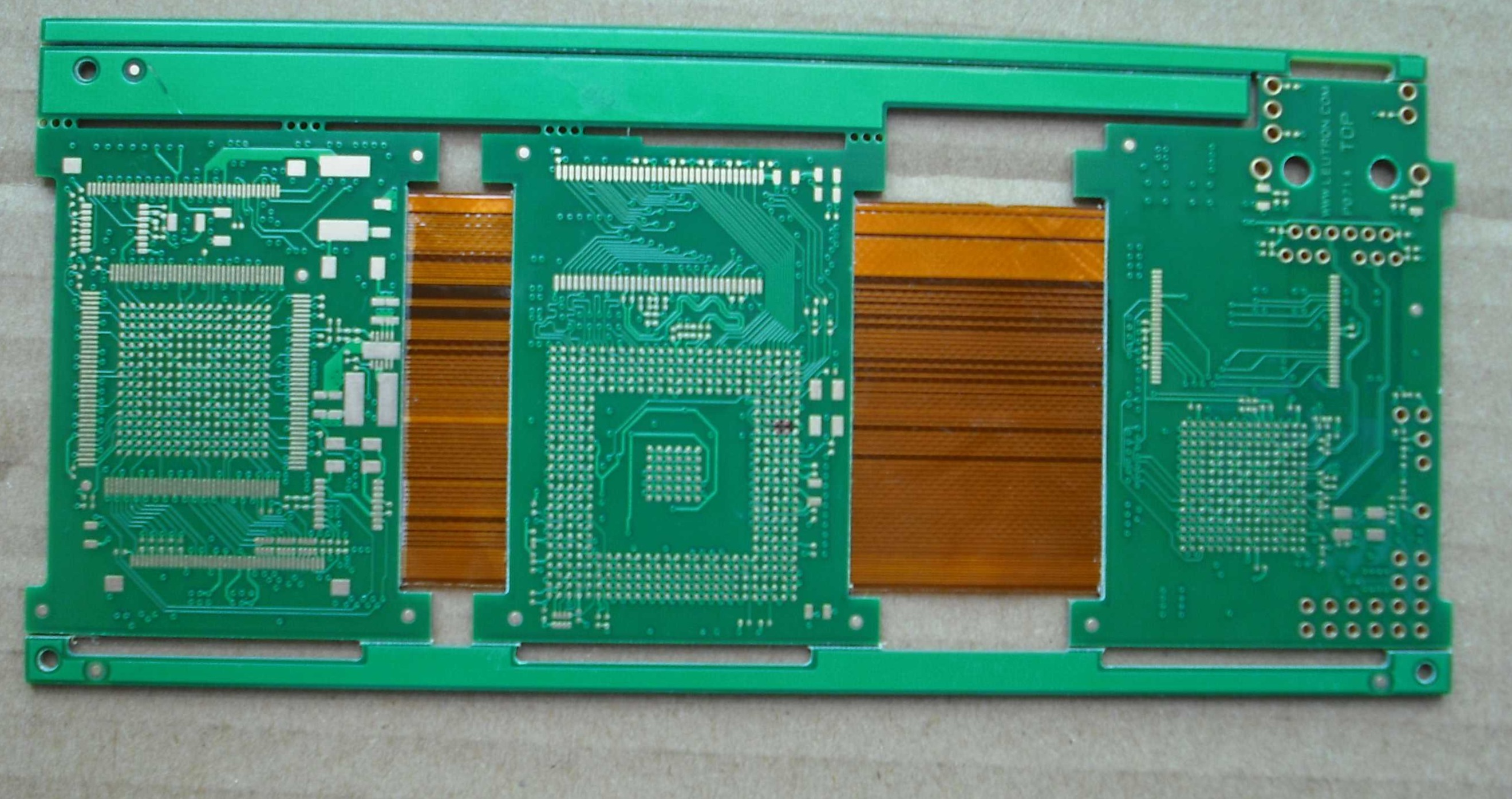

10 Layer rigid-flex PCB made by Storm Circuit

10 Layer rigid-flex PCB made by Storm Circuit

PCB layers:10 layers

Material:FR4+PI

Thickness:1.6mm +0.2mm

Min track/space:0.13/0.13mm

Immersion Gold¥ 0.00Buy now