-

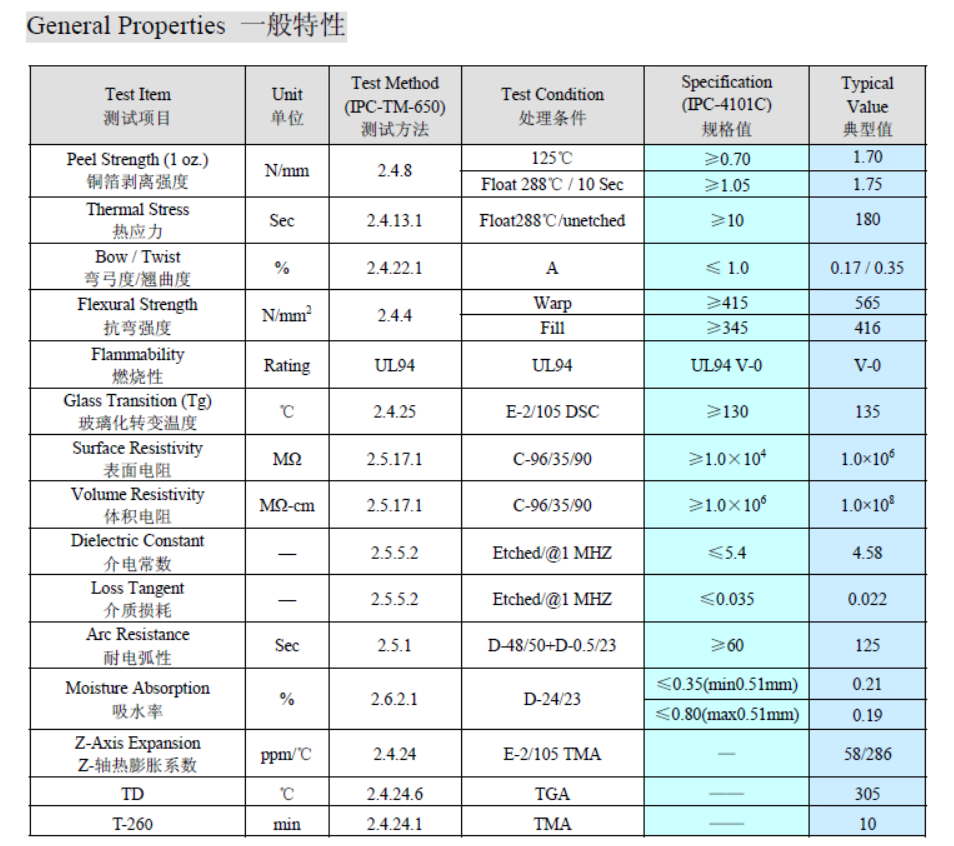

Normal FR4 material with TG130-135.

Applications: Reinforcement laminate, Potentiometer, Resistance,

Comsumer electronics,Toys,etc- UVB and AOI

- Excellent heat resistance and mechanical properties

- IPC-4101C/21 specification is applicable

-

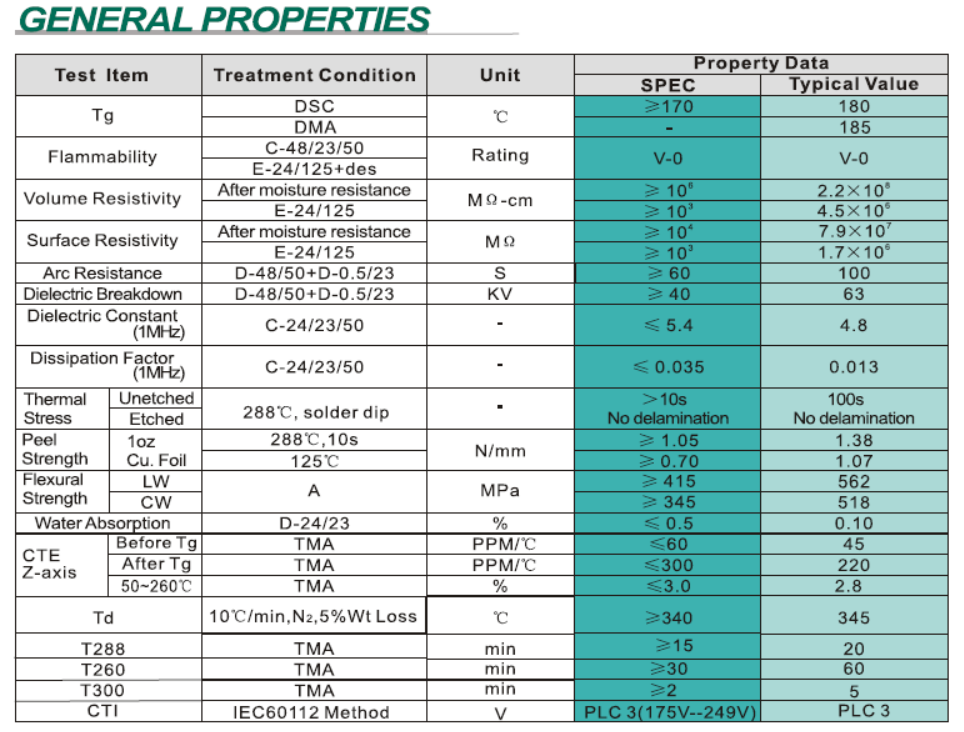

Applications:

Suitable for high aspect ratio and high layer PCB.Widely used in computer,communication equipment,precise apparatus and instrument,router,medical

equipment,etc.

Datasheet

- Shengyi S1000-2

- ITEQ IT-180

- ISOLA FR408 FR408 is widely be replaced with S1000-2 or IT-180 or TU-768

- TUC TU-768 (any layer HDI PCB,we prefer use TU-768 material).

- Higher heat resistance;

- Lower Z-axis CTE;

- Excellent thermal stress resistance;

- High thermal shock resistance;

- Excellent PTH reliability.

-

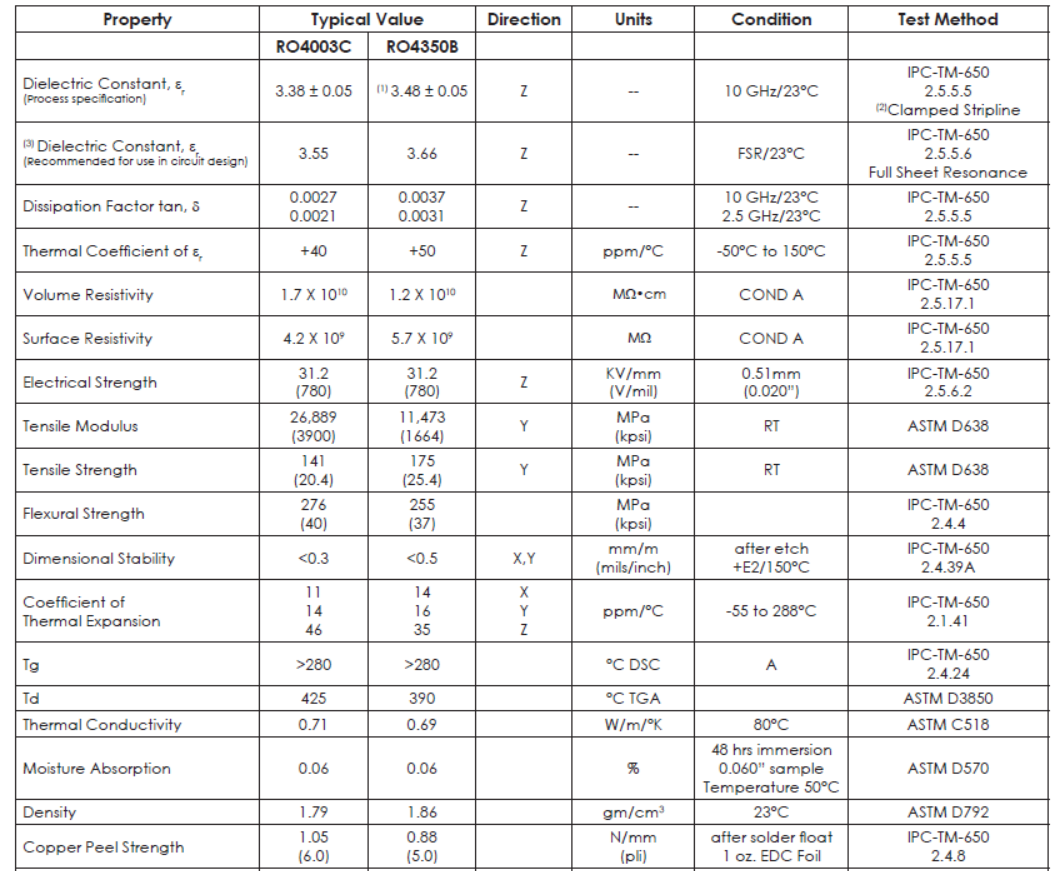

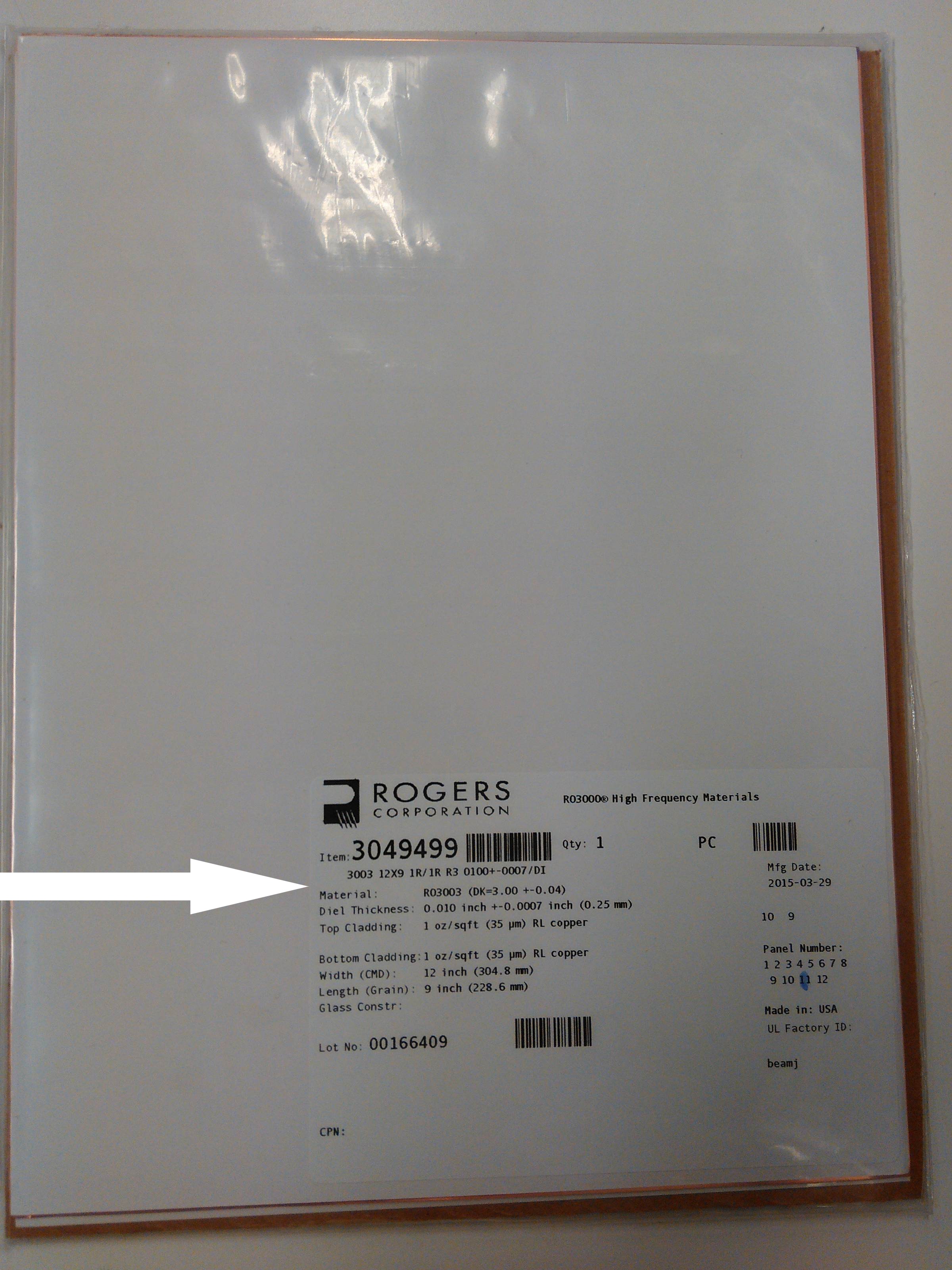

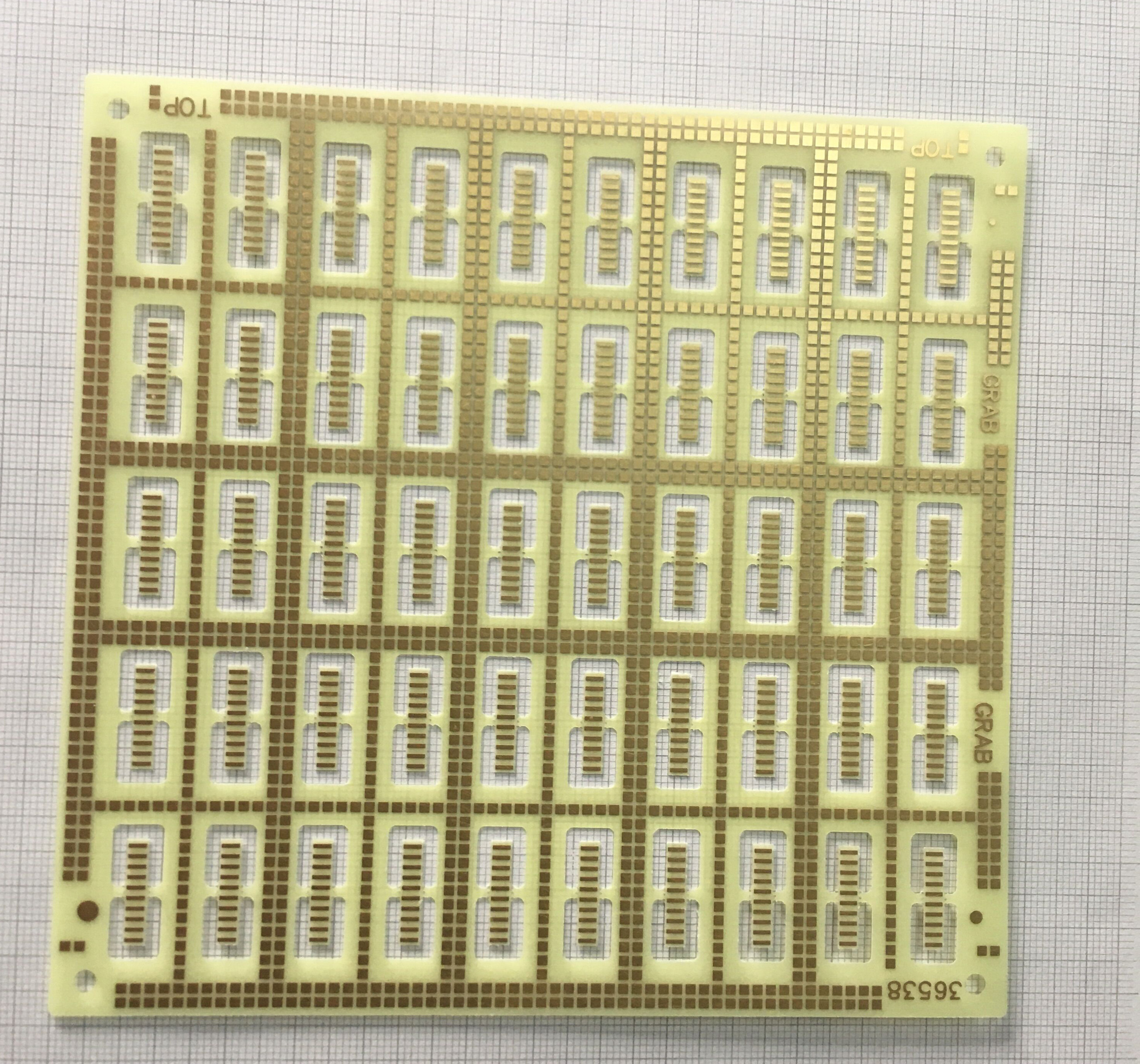

High Frequency material (RF board,Microwave)

Applications:Cellular Base Station Antennas and Power Amplifiers.RF Identifi cation Tags.Automotive Radar and Sensors.LNB’s for Direct Broadcast Satellites,etc

See our RF board.- Rogers RO4000 series

- Tacanic TLX series RF35

- Arlon AD250 series ,TC350L

- PTFE, F4B, F4BM,

- Low dielectric tolerance and low loss

- Stable electrical properties vs. frequency

- Low Z-axis expansion

- Low in-plane expansion coeffi cient

-

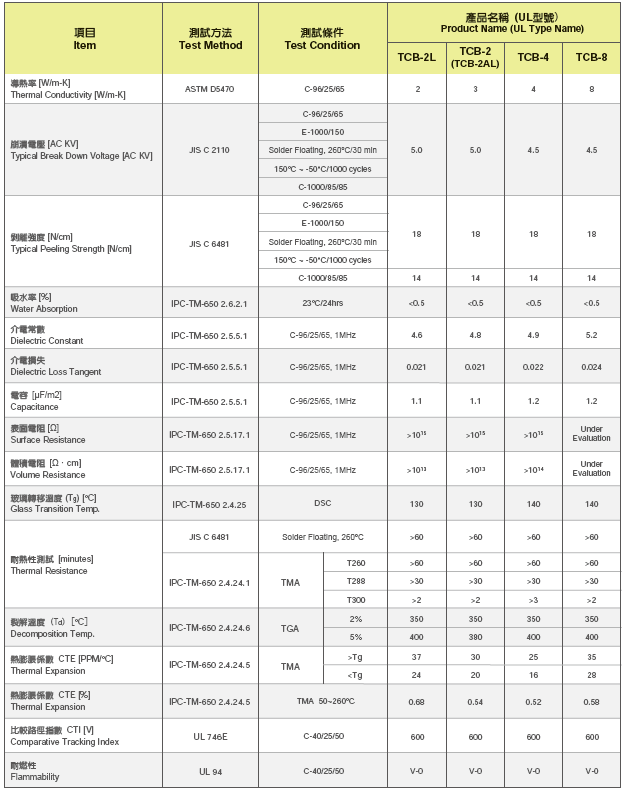

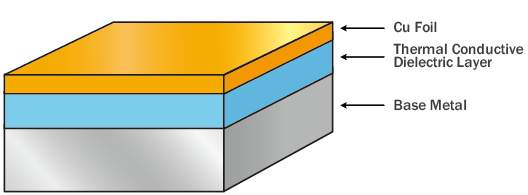

Thermal Conductive Board (TCB), or Insulated Metal Substrate (IMS), provides the advantages of high thermal conductivity, reliability

and solder heat endurance. The TCB substrate is a sandwich structure, which includes layers of conductor, insulator and metal base.

Traditionally, this insulator is made of epoxy, epoxy filled glass fiber, polyimide, or other dielectric materials. However, these kinds of

insulators could not meet the requirement in high-power electronic devices. The heat generated by these devices will accumulate, and

the life time and reliability of the end product will decrease -

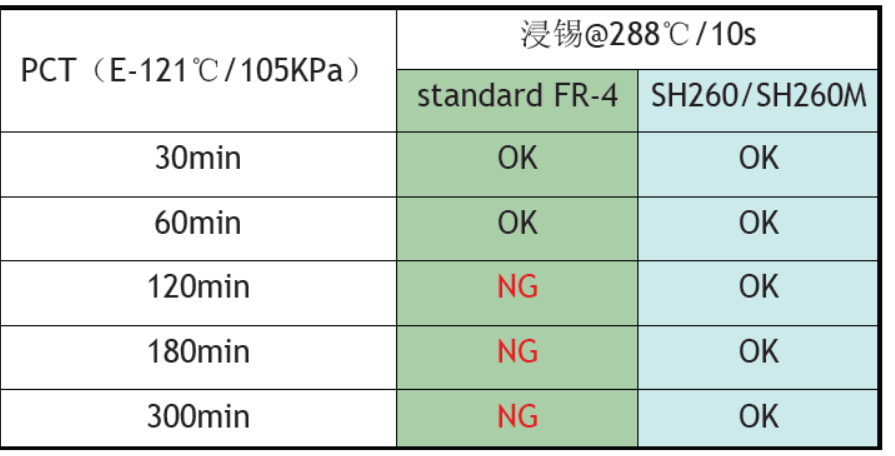

SH260 are widely used in Aeronautics and Astronautics,Ultra multi-layer PCB (>10 layers),Outdoor PCB,Long-term High Temperature Environment PCB.Coal Mine ,very low CTE etc.

- Arlon 85N

- ShengYi SH260

Properties Condition Unit SH260 1.2mm H/H Arlon 85N 1.0mm H/H tg TMA ℃ 255 ﹥250 Td 5% Loss,10℃/min@N2 ℃ 423 416 Thermal resistance T300 min ﹥60 ﹥60 Flammability UL 94 -- HB HB Water absorption PCT‐105KPa/120min % 0.36 0.54 PCT (2 Hours) dipping@288℃,10 Sec -- ﹥10 X ﹥10 X Z‐axis CTE (50‐260 ℃) TMA % 1.2 1.2 Dielectric breakdown D‐48/50+D‐0.5/23 kV kV40.5 -- Peel strength 288℃/10s N/mm 1.19/1.23 1.10/1.17 Flexural strength @200 ℃ GPa 20.5 --- -

Halogen-free material

ShengYi S1170G

- Anti-CAF capability

- Lead-free compatible

- Excellent through-hole reliability

- Halogen, antimony and red phosphorous free

CEM-3 material Q260

CEM-3 material has a better thermal conductivity than normal FR4.

And it has CTI PROPERTIES but lower cost than Aluminum material. A few of customers would like to use CEM-3 now.

Applications:

Power base board

LED display and lighting

Household electrical machinePanasonic material

Panasonic M7 material is an Ultra-low transmission loss Highly heat resistant Multi-layer circuit board materials.

Laminate R-5785(GN) R-5785(N)

Prepreg R-5680(GN) R-5680(N)

Features:- Dk 3.4 Df 0.002@12GHz

- Tg (DSC) 200℃

- T288 (with copper) >120min

High CTI 600V PCB

CTI is Comparative Tracking Index.

CTI is a quality item that refers to copper clad laminate which is widely used in home electrical appliance or other high-voltage(110V, 220V) electrical apparatus.It is a simulated conditon that the PCB is polluted in its working environment, which result in leakage or short-circuit at the track gap of the PCB surface, being accompanied by heat releasing and charring.

ShengYi S1600- CTI>600V

- Tg 135

- Td 310

Storm Circuit PCB Material Center

PCB Material Center

Printed circuit board is the most important part of electronics. The PCB material is the most cost of the whole PCB. So,before PCB design, you need to know which material is the best for your product.PCB design is just a first step,you also need to know the application environment of PCB,such as outdoor,underwater,high temperature.Good meterial can support long life for your eletrical equipments.

Storm Circuit has many different materials for you to choose. What customers need,then we will do .

RO3003 material,a full sheet

0.2mm Polyimide PCB,ENEPIG

-

ꁸ Top

-

ꂅ 075528363585

-

ꀥ QR code

How to choose PCB material?

-

2022-06-01 KB-6164.pdf

끂265 177.92 KB -

2022-06-01 RF35.pdf

끂250 143.89 KB -

2022-06-01 RO3000.pdf

끂249 242.84 KB -

2022-06-01 RO4000.pdf

끂255 186.71 KB -

2022-06-01 Rogers RF material select guide.pdf

끂274 13.78 MB -

2022-06-01 S1000-2.pdf

끂254 2.15 MB -

2022-06-01 S1600 CTI.pdf

끂236 541.55 KB -

2022-06-01 SH260.pdf

끂247 843.54 KB -

2022-06-01 TU-768.pdf

끂225 299.58 KB -

2022-06-01 无卤SDI03KB.pdf

끂247 370.09 KB -

2022-06-06 S1141.pdf

끂248 1.13 MB -

2022-06-06 IT180.pdf

끂240 169.95 KB -

2022-06-06 TU-768.pdf

끂235 299.58 KB -

2022-06-06 FR-408.pdf

끂251 339.04 KB -

2022-06-06 CEM-3 Q260.pdf

끂216 644.71 KB -

2022-07-19 85N-Polyimide.pdf

끂221 242.25 KB -

2022-07-19 松下M7.pdf

끂208 127.67 KB

The key parameters for PCB material are Tg,Dk,Df,CTE,etc. Here we have a PCB material's parameters list for you to reference.

-

2022-06-07 material parameters.pdf

끂239 229.01 KB

To select the right PCB material, you need to see a few factors. If you know about the factors that you need to look at, then you can easily get the best PCB material for your project, and the PCB will provide the required results. You can also talk to the PCB manufacturer or fabricator about these factors. Let’s look at the factors that are essential to consider while selecting a PCB material.

A) Tg:Glass Transition Temperature

The substrate should have a high glass transition temperature (Tg). A high Tg can deal with heat dissipation and ambient temperature. You must select those materials that have a higher Tg than the circuit temperature. Otherwise, the substrate will melt down or bend during the operation. >=8 layers PCB,Storm PCB must use >Tg170 PCB material .Tg150 or less is not safe for high layer PCB.

B) CTE:Coefficient of Thermal Expansion

The PCB material should have a low coefficient of thermal expansion. If the coefficient is high, then it will expand more per unit increase in temperature. This will affect the length, width, and thickness of the PCB board. The PCB will change its shape easily and may cause damage to the board and components. Make sure to select the material that has a low coefficient of thermal expansion.

C) Heat Resistance

High heat resistance is required. Generally, PCB must have a heat resistance of 250 ℃ / the 50S. If you need more heat resistance, then you can discuss it with your PCB manufacturer.

D) Flatness

There should be excellent flatness. The warpage should be less than 0.0075mm / mm.

E) Dielectric Constant and Losses

The PCB material should have an excellent dielectric constant. It will provide excellent insulation and offer the desired results. Moreover, the dielectric losses should be low to save energy.Dk and Df is very important for high frequency PCB.very low loss is usually RF material ,Rogers RO400.

F) Degree of Bending

The PCB should not bend easily. If it bends on the ambient temperature of the device where it is installed, then it will wear quickly. It will not last for a long time. Therefore, the PCB should have a low degree of bending so that it cannot bend on the circuit operating temperature. Its heat resistance should be high, depending on the place where it will be used. Some substrates, like FR-4 have a low degree of bending, which is suitable. The degree of bending matters a lot when the PCB is larger than 3.2 × 1.6mm. Due to the large size, it is affected more due to bending. So, you need to be more careful in the case of large PCBs. Moreover, the appearance is required to be smooth and flat without warpage, cracks, scratches, and rust.

Also,there are many other factors,such as voltage (if you apply in high voltage,CT>600V)

Storm Circuit Technology Ltd, Made in China with Love.

2009-2022