2 layer double sided copper core --Thermal Direct PCB

The MCPCB material is very important for thermal conductive.

Thermal Substrates (MCPCB) Intro:

What is a Thermal Substrate?

--Metal clad printed circuit board used for surfacemount components and COB technologies

--Used to efficiently remove heat from the components, transfer and spread it in the metal substrate

--It gives a very good thermal / mechanical means of connecting to a heat sink

--It provides the best solution available to improve system performance and reliability by reducing component temperature.

Choosing the appropriate MCPCB material stack up

Substrate material selection can vary with LED selection

-- The lower the thermal resistance of the LED package the greater the

need for a higher performing substrate material

a) Copper circuit foil thickness is selected based on current carrying capacity

needed and surface heat spreading objectives

b) Dielectric thermal performance is selected based on LED’s thermal

resistance & power density

c) Base metal is selected based on thermal performance and

mechanical/structural requirements

Single Layer – most common

- Double Layer – increased routing area

- Ultra Thin Substrate – can be formed

Advanced Substrate Technology

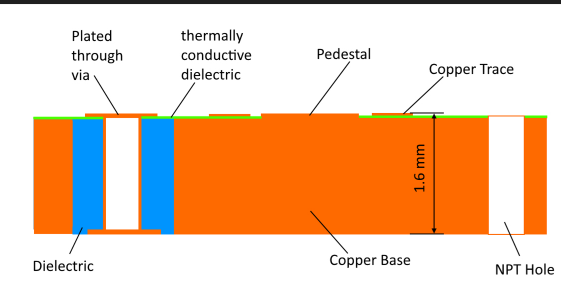

Active Copper Base Plate

--Copper base with blind plated via’s

--Can be a multilayer construction

--Laser drilling can enable the hole to stop at any copper layer

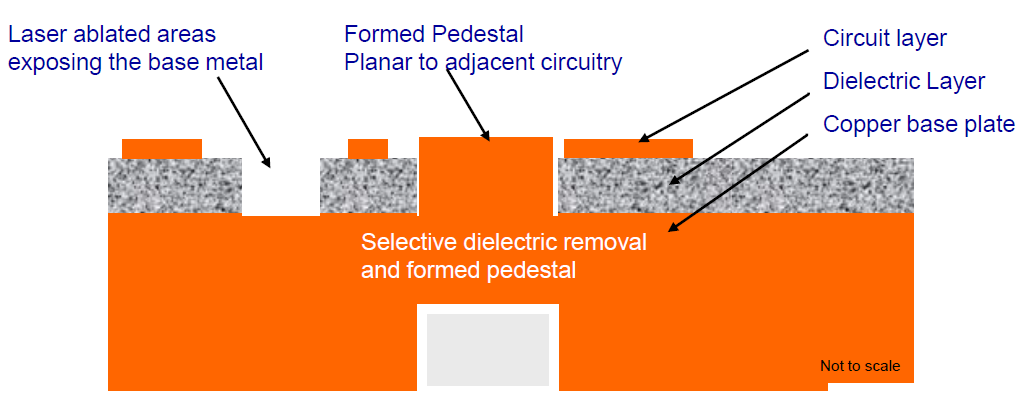

BergquistSelective Dielectric Removal

--Selective removal of dielectric -using a Co2 laser

--Tight tolerance capability -±0.05mm feature size and positional accuracy

--Reduce thermal resistance by mounting components directly to base metal

Formed Pedestal

•Form base metal to be planar with adjacent circuits

•Minimizes solder bond line when component or die attach to base metal